Thermal Insulation Decorative Sandwich Panel Machine

As an innovative tool in the modern construction industry, the Thermal Insulation Decorative Sandwich Panel Machine has injected new vitality into the development of the construction industry with its advantages of efficient production, precise control, energy conservation and environmental protection, and diversified design.

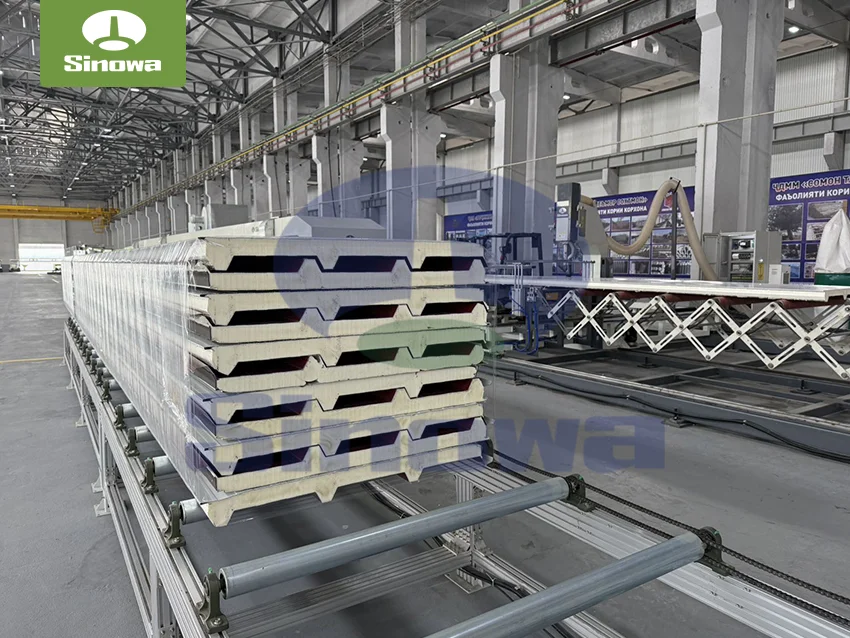

The insulation decorative sandwich panel machine is a production equipment that integrates automation and intelligence. It produces sandwich panels with excellent insulation performance and decorative effect in one go by precise cutting, bonding, pressing and other processes of raw materials such as insulation materials, decorative panels and core materials. Specifically, the machine uses a precise control system to precisely process raw materials according to preset parameters, ensuring that each sandwich panel has stable quality and performance.

Advantages of Thermal Insulation Decorative Sandwich Panel Machine

Efficient production: The insulation decorative sandwich panel machine adopts an automated production line, greatly improving production efficiency. Compared to traditional manual production methods, machine production can complete cutting, bonding, pressing and other processes more quickly, thereby shortening the production cycle and reducing production costs.

Precise control: The machine is equipped with an advanced control system that can accurately control the processing accuracy and size of raw materials, ensuring that each sandwich panel meets the design requirements. This precise control not only improves the quality stability of the product, but also reduces the waste of raw materials.

Energy saving and environmental protection: The insulation and decoration sandwich panel machine adopts energy-saving and environmental protection technologies and processes in the production process. For example, by optimizing cutting and bonding processes, energy consumption and waste emissions have been reduced. At the same time, sandwich panels themselves also have good insulation performance, which helps to reduce the energy consumption of buildings.

Diversified design: This machine can produce sandwich panels in various colors, textures, and shapes to meet the personalized needs of different customers. This diversified design not only enhances the aesthetics of the building, but also increases the market competitiveness of the product.

With the rapid development of the modern construction industry, insulation and decorative sandwich panel machines have been widely used in various construction projects. For example, in residential, commercial, industrial and other fields, sandwich panels are used as insulation and decorative materials for exterior walls, roofs, partitions and other parts. Its excellent insulation performance and decorative effect not only improve the comfort and aesthetics of buildings, but also help reduce energy consumption and carbon emissions.

In addition, Thermal Insulation Decorative Sandwich Panel Machines have also promoted the green development of the construction industry. By using environmentally friendly materials and processes, the production and use of sandwich panels are more in line with the concept of sustainable development. Meanwhile, sandwich panels, as a lightweight and high-strength building material, also contribute to reducing the weight of buildings and improving their seismic performance.

Related

External Wall Insulation Board Assembly Line

Working Principle Of PU Sandwich Panel Machine

Supply Automatic Foaming Production Line

Roof and Wall Panel Production Line

Custom Insulation Sandwich Panel Machine

PIR Insulated Partition Panel Production Line

Benefits Of PU Insulation Board Production Line

Continuous PU Sandwich Panel Line For Color Steel Sheet

Newest Sandwich Panel Line

PU Sandwich Panel Line For Cold Storage Construction With Thermal Insulation