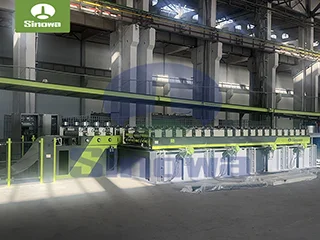

Benefits Of PU Insulation Board Production Line

The PU Insulation Board Production Line has many advantages such as efficient automation production, energy conservation and environmental protection, flexibility and scalability, high-quality product output, and intelligent management. These advantages make the polyurethane insulation board production line highly competitive in the market and able to meet the needs of different customers for high-quality insulation materials.

The Benefits of the PU Insulation Board Production Line are mainly reflected in the following aspects:

Efficient automated production

The PU Insulation Board Production Line usually integrates multiple functions such as uncoiling, laminating, cutting, forming, preheating, foaming, curing, cutting, cooling, stacking and conveying, packaging, etc., achieving highly automated production. This automated production mode not only improves production efficiency, but also significantly reduces manual operations and lowers labor costs. Meanwhile, automated production lines can ensure the stability and consistency of product quality, enhancing the market competitiveness of products.

Energy conservation and environmental protection

The PU Insulation Board Production Line pays attention to the application of energy-saving and environmental protection technologies in the design and manufacturing process. For example, using multi-component cyclopentane foaming technology and equipment can not only save a lot of costs, but also have significant implications for environmental protection. In addition, the production line takes corresponding measures to reduce energy consumption levels at high energy consumption points, such as covering insulation boards outside the laminated conveyor body and adopting a reasonable structure to increase thermal insulation performance, thereby reducing overall energy consumption.

Flexibility and Scalability

PU Insulation Board Production Lines usually have modular designs that can be flexibly configured according to different production needs. This modular design enables the production line to easily adapt to the production of polyurethane insulation boards of different specifications and types, improving the flexibility and scalability of the production line. Meanwhile, modular design also facilitates later maintenance and upgrades, reducing production costs.

High quality product output

The PU Insulation Board Production Line can produce polyurethane insulation boards with excellent performance. These insulation boards have excellent characteristics such as lightweight, high strength, insulation, sound insulation, moisture resistance, and fire resistance, and are not affected by natural conditions, without problems such as insect infestation, mold growth, and warping deformation. These high-quality products have been widely used in building exterior wall insulation systems, meeting the market's demand for high-quality insulation materials.

Intelligent management

Modern PU Insulation Board Production Lines are usually equipped with advanced control systems and monitoring equipment, achieving intelligent management of the production process. By dynamically monitoring the working status of the entire production line through industrial PC, real-time information such as production progress, equipment status, and product quality can be obtained. This intelligent management not only improves production efficiency, but also reduces management costs, making the production process more transparent and controllable.

Related

Insulated PU Sandwich Panel Line

High Quality PU Sandwich Panel Machine Design

Corrugated Sandwich Panel Production Line

External Wall Composite Insulation Board Production Line

Sandwich Panel Forming Machine

Thermal Insulation Decorative Sandwich Panel Machine

PU Sandwich Panel Machine Manufacturer From China

Sandwich Panel Line For Cold Storage

PIR Insulated Sandwich Panel Machine

Cold Room Panel Production Line