PU Sandwich Panel Manufacturing Plant For Cold Room Panel Production

In the modern cold chain logistics system, cold storage facilities play a pivotal role in preserving the quality and safety of perishable goods, ranging from fresh food to pharmaceutical products. At the core of these facilities lies the cold room panel, a component that directly determines the insulation efficiency, temperature stability, and long-term operational costs of the cold storage. Among the various materials used for cold room panels, polyurethane (PU) sandwich panels stand out due to their exceptional thermal insulation performance, structural integrity, and durability. The manufacturing plant dedicated to producing PU sandwich panels for cold room applications is a sophisticated integration of advanced technology, precise process control, and strict quality management, ensuring that each panel meets the rigorous requirements of low-temperature storage environments.

The production of PU sandwich panels for cold rooms begins with the careful selection of raw materials, as the quality of input materials directly impacts the final performance of the panels. The main components of a PU sandwich panel include the outer facing materials, the PU foam core, and the adhesive system that bonds these layers together. For the outer facings, common materials include color-coated steel sheets, stainless steel sheets, and aluminum panels, each chosen based on the specific application environment of the cold room. Color-coated steel sheets are widely used for general cold storage applications due to their cost-effectiveness and good corrosion resistance, while stainless steel sheets are preferred for cold rooms in food processing or pharmaceutical industries where hygiene and resistance to harsh cleaning agents are critical. Aluminum panels, particularly those with embossed surfaces, are selected for environments with high humidity, such as seafood cold storage, as they offer excellent resistance to moisture and corrosion.

The PU foam core, the heart of the sandwich panel's insulation performance, is formulated using polyol and isocyanate as the main raw materials, combined with additives such as flame retardants, foaming agents, and catalysts. The selection of these chemicals is crucial to achieving the desired thermal conductivity, density, and fire resistance properties. High-quality PU foam for cold room panels typically has a closed-cell rate of over 92%, which effectively prevents heat transfer and avoids the formation of cold bridges—phenomena that can significantly reduce the insulation efficiency of the cold room. The foaming agent used must be environmentally friendly, avoiding substances that contribute to ozone depletion or global warming, in line with the growing global emphasis on sustainable production.

Once the raw materials are selected and inspected, the manufacturing process proceeds to the pre-processing stage of the facing materials. This stage involves cutting, bending, and profiling the metal sheets to the required dimensions and shapes using advanced numerical control (NC) equipment. The use of NC cutting machines ensures that the metal sheets are cut with high precision, with a tolerance of less than 0.5mm, which is essential for achieving tight and seamless joints during panel assembly. Bending machines, also controlled by computer numerical control, shape the edges of the metal sheets into specific profiles, such as tongue-and-groove structures, which enhance the sealing performance of the panels when they are installed in the cold room. Additionally, the metal sheets may undergo surface treatment processes, such as galvanizing or coating with anti-corrosive paints, to further improve their durability and resistance to environmental factors.

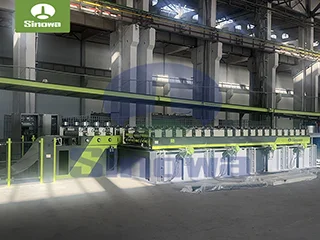

The core of the PU sandwich panel manufacturing process is the foaming and lamination stage, where the PU foam core is formed and bonded to the pre-processed facing materials. This stage is typically carried out using a continuous production line, which ensures consistency in the quality of the panels and high production efficiency. The process begins with the feeding of the two outer facing materials into the production line, where they are guided through a series of rollers to maintain flatness and proper alignment. Meanwhile, the polyol, isocyanate, and additives are precisely mixed in a high-pressure foaming machine at a controlled temperature and pressure. The high-pressure mixing ensures that the raw materials react uniformly, producing a foam with consistent density and cell structure.

The mixed foam is then injected between the two facing materials as they move through the production line. The assembly is then passed through a series of compression rollers and a curing tunnel, where the foam expands and cures under controlled temperature and humidity conditions. The curing process is critical to the formation of the PU foam's mechanical and thermal properties; insufficient curing can result in poor bonding between the foam core and the facing materials, as well as reduced insulation performance. The continuous production line allows for the adjustment of the panel thickness, ranging from 50mm to 250mm, to meet the different temperature requirements of cold rooms—thicker panels for low-temperature freezers (such as -35℃速冻 rooms) and thinner panels for high-temperature refrigerated warehouses (such as 0℃ to 10℃ fresh food storage rooms).

After the foaming and lamination process, the continuous panel is cut into individual panels of the required length using a flying saw, which operates synchronously with the production line to ensure clean and precise cuts. The cut panels then undergo a series of post-processing treatments, including edge trimming, cleaning, and quality inspection. Edge trimming removes any irregularities from the panel edges, ensuring that they fit perfectly with adjacent panels during installation. The panels are then cleaned to remove any dust, debris, or excess foam from the surface, preparing them for packaging and delivery.

Quality control is an integral part of every stage of the manufacturing process, ensuring that the final PU sandwich panels meet the strict performance requirements for cold room applications. Raw material inspection involves testing the chemical composition, mechanical properties, and surface quality of the metal sheets, polyol, isocyanate, and additives. For example, the thermal conductivity of the PU foam is tested to ensure it is below 0.024 W/(m·K), a key indicator for achieving effective insulation in cold rooms. During the production process, in-line quality checks are performed to monitor the thickness of the foam core, the bonding strength between the foam and the facing materials, and the flatness of the panels. The bonding strength is particularly important, as it must be at least 0.12 MPa to ensure the structural integrity of the panel under the static and dynamic loads encountered during transportation and installation.

Finished product inspection includes a comprehensive range of tests, such as density measurement, compressive strength testing, fire resistance testing, and dimensional accuracy checking. The density of the PU foam core is typically controlled within the range of 40±2 kg/m³, ensuring a balance between insulation performance and structural strength. Compressive strength tests verify that the panels can withstand the loads imposed by the cold room structure and stored goods, with a minimum requirement of 150 kPa. Fire resistance testing ensures that the panels meet the required fire safety standards, with most cold room panels achieving a grade of B1 (flame-retardant) to reduce the risk of fire spread in the cold storage facility. Dimensional accuracy checks confirm that the length, width, and thickness of the panels are within the specified tolerances, ensuring ease of installation and proper sealing.

The manufacturing plant also pays close attention to environmental protection and energy efficiency in its operations. The foaming process is designed to minimize the emission of volatile organic compounds (VOCs) by using low-VOC raw materials and installing efficient ventilation systems. Waste materials, such as off-cuts of metal sheets and excess foam, are collected and recycled to reduce environmental impact. Additionally, the production line is equipped with energy-saving equipment, such as variable-frequency drives for motors and heat recovery systems, which reduce energy consumption and lower the carbon footprint of the manufacturing process.

The PU sandwich panels produced by the manufacturing plant are widely used in various types of cold storage facilities, each with specific requirements that the panels are designed to meet. Food processing cold rooms, for example, require panels that are easy to clean, hygienic, and resistant to corrosion from food juices and cleaning agents. In these applications, stainless steel-faced PU panels are often used, as they have a smooth surface that can be easily sanitized and are resistant to chemical attack. Pharmaceutical cold rooms, which store temperature-sensitive drugs and vaccines, require panels with high insulation precision to maintain a constant temperature range of 2℃ to 8℃. These panels typically have a low thermal conductivity and excellent airtightness to prevent temperature fluctuations.

Logistics transit cold rooms, which experience frequent door openings and high traffic, require panels with high impact resistance and good sealing performance. The tongue-and-groove joint design of the PU sandwich panels ensures that even with frequent use, the panels maintain a tight seal, reducing cold air loss and energy consumption. Small commercial cold rooms, such as those in convenience stores or restaurants, benefit from the lightweight and easy-to-install nature of PU sandwich panels, which allow for quick construction and minimal disruption to business operations.

In addition to meeting the immediate requirements of cold room construction, the PU sandwich panels produced by the manufacturing plant also contribute to the long-term operational efficiency of the cold storage facilities. Their excellent insulation performance reduces the energy consumption of the refrigeration system, which is typically the largest energy consumer in a cold room. Studies have shown that high-quality PU sandwich panels can reduce the energy consumption of a cold room by up to 30% compared to panels with lower insulation performance. This not only lowers the operational costs for the cold storage operator but also reduces the facility's environmental impact by decreasing greenhouse gas emissions.

The durability of PU sandwich panels also ensures that the cold room has a long service life, minimizing the need for frequent maintenance or replacement. The panels are resistant to moisture, corrosion, and aging, and can withstand the harsh conditions of low-temperature environments without significant degradation. With proper installation and maintenance, PU sandwich panels can last for more than 25 years, providing a reliable and cost-effective solution for cold storage construction.

As the global demand for cold chain logistics continues to grow, driven by factors such as urbanization, changing consumer preferences for fresh and frozen foods, and the expansion of the pharmaceutical industry, the importance of high-quality PU sandwich panels for cold room applications is set to increase. Manufacturing plants dedicated to producing these panels are constantly innovating, adopting new technologies and materials to improve the performance, sustainability, and cost-effectiveness of their products. For example, the development of composite PU panels with aerogel insulation layers is enabling the production of thinner panels with the same or better insulation performance as traditional thicker panels, reducing material usage and transportation costs.

Another area of innovation is the integration of smart technologies into the manufacturing process, such as the use of Internet of Things (IoT) sensors to monitor the production line in real-time. These sensors can detect deviations in temperature, pressure, or material flow, allowing for immediate adjustments to be made to ensure product quality. Additionally, digital modeling and simulation tools are being used to optimize the design of the panels, ensuring that they meet the specific requirements of different cold room applications while minimizing material waste.

In conclusion, the PU sandwich panel manufacturing plant for cold room panel production is a critical component of the global cold chain infrastructure. Through the careful selection of raw materials, precise process control, and strict quality management, these plants produce panels that offer exceptional thermal insulation, structural integrity, and durability. The panels not only meet the diverse requirements of different cold storage applications but also contribute to energy efficiency, environmental sustainability, and long-term operational cost savings. As the cold chain industry continues to evolve, the manufacturing plants will continue to innovate, driving the development of more advanced and sustainable PU sandwich panels to support the growing demand for safe and efficient cold storage solutions.

Related

Thermal Insulation Decorative Sandwich Panel Machine

Energy-Efficient PU Sandwich Panel Making Line With Low Power Consumption

PU Sandwich Panel Machine With Auto Packer

PU Sandwich Panel Machine Manufacturer From China

PU Sandwich Panel Machine With Fire Retardant Foam Core

Sandwich Panel Line For Cold Storage

PUF Sandwich Panel Line With Automatic PU Mixing Head And Injection System

PIR Insulated Sandwich Panel Machine

PU Sandwich Panel Line For Fire-Proof Panels

Cold Room Panel Production Line