Heavy-duty PU Sandwich Panel Production Line For Industrial Building Panels

The polyurethane sandwich panel is an important building material in the field of contemporary industrial architecture. It is composed of two layers of high-strength metal panels (usually aluminum zinc plated steel plate or stainless steel plate) and the middle polyurethane rigid foam core material through a special process. This sandwich structure material has excellent thermal insulation performance, high strength to weight ratio, and excellent fire resistance, and is widely used in large industrial plants, logistics warehouses, cold storage and other places that require high-strength enclosure structures.

Compared with traditional building materials, the products produced by heavy-duty pu sandwich panel production lines have the following advantages:

The compressive strength can reach over 150kPa

Thermal conductivity as low as 0.022W/(m · K)

The fire rating can reach B1 level or higher

The service life can reach more than 25 years

Installation efficiency increased by 60% compared to traditional building materials

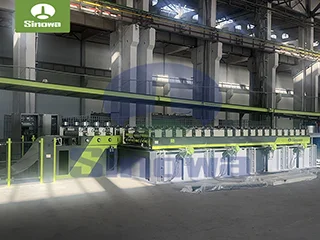

The heavy-duty polyurethane sandwich panel production line is a highly automated integrated system, which mainly includes the following key equipment:

Automatic feeding system:

Double station steel plate unwinding machine

Automatic correction device

Board cleaning unit

Pre treatment spraying systemForming unit:

Multi roll continuous cold bending forming machine (12-24 sets of rollers)

Online size detector

Automatic cutting device

Waste recycling systemPolyurethane foaming system:

High pressure foaming machine (working pressure 150-250bar)

Accurate temperature control system (± 0.5 ℃)

Polyol and isocyanate storage tanks

Automatic mixing head and cleaning deviceComposite curing section:

Double layer crawler press

Infrared preheating device

Temperature controlled solidification tunnel (length 30-60 meters)

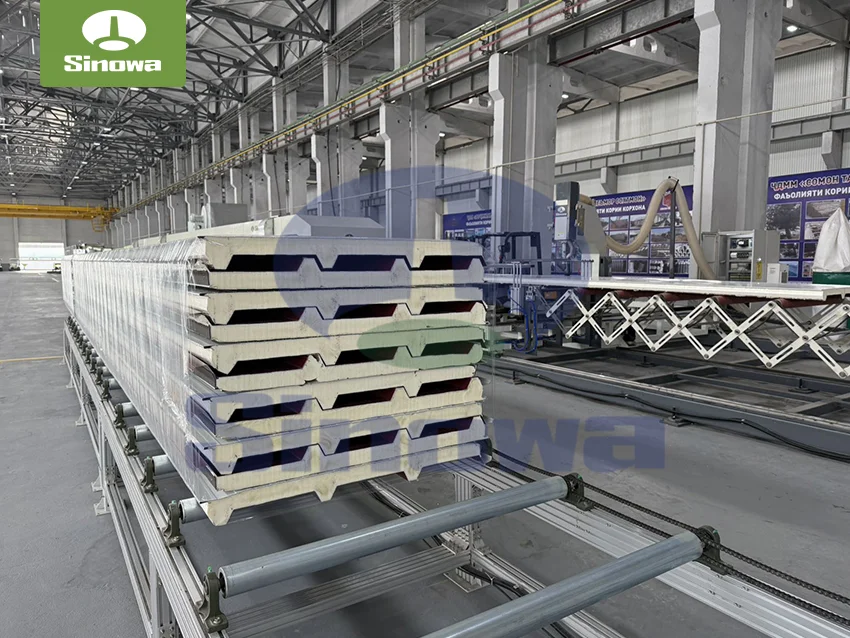

cooling systemPost processing and packaging:

Automatic trimming machine

Finished cutting saw

Packaging automation system

Stacking robot

The production of polyurethane sandwich panels is a precision controlled continuous process:

Panel preprocessing:

After being uncoiled and leveled, the steel plate enters the cleaning section to remove surface oil stains

Apply anti-corrosion primer by roller coating or spray coating

Complete coating curing in the drying oven (temperature 180-220 ℃)Panel Forming:

The preprocessed panel enters the continuous cold bending forming machine

Gradually form the required plate shape through multiple sets of precision rollers

Real time monitoring of molding accuracy using online laser rangefinderPolyurethane foam:

High pressure foaming machine mixes polyols and isocyanates in precise proportions

The mixture is transported to the composite section through a temperature controlled pipeline

Inject foam material between the upper and lower formed panelsComposite curing:

The slab enters the double-layer track press to control the foam thickness and density

Fully cure polyurethane through temperature controlled tunnel

The cooling section reduces the plate temperature to below 40 ℃Fixed length cutting:

Automatically measure and cut according to order requirements

The adjustable range of oblique angle is 30 ° -60 °

Cutting accuracy controlled within ± 1mmQuality inspection and packaging:

Automatically detect board thickness, flatness, and appearance

Automated stacking by robotic arm

Wrapped packaging or customized wooden crate packaging

The pu sandwich panel line products are mainly used for:

Large industrial plant walls and roofs

Cold Chain Logistics Center

Aerospace facilities

clean room

Modular architecture

Related

Polyurethane Edge Banding Sandwich Panel Machine

Polyurethane Roof Sandwich Panel Machine

High-end Polyurethane Sandwich Panel Production Line Manufacturer In China

Insulated PU Sandwich Panel Line

High Quality PU Sandwich Panel Machine Design

Corrugated Sandwich Panel Production Line

External Wall Composite Insulation Board Production Line

Sandwich Panel Forming Machine

Thermal Insulation Decorative Sandwich Panel Machine

PU Sandwich Panel Machine Manufacturer From China