Foam Sandwich Board Machine

The foam sandwich panel machine is the core equipment used to produce color steel sandwich panels. By combining color steel plates with foam (polyurethane), rock wool and other thermal insulation materials, building panels with thermal insulation, fire prevention and sound insulation functions are formed. Widely used in fields such as activity rooms, cold storage, and factory exterior walls.

The foam sandwich panel machine is an indispensable professional equipment in the modern construction industry, which is used to produce composite panels with excellent thermal insulation performance. This type of equipment combines high-strength outer materials (such as color steel plates) with lightweight insulation core materials (such as polyurethane, rock wool, etc.) to manufacture building materials widely used in industrial plants, cold storage, purification workshops, and other places.

Foam sandwich board machine is an industrial equipment specially used to produce color steel composite board. According to the type of filler, it can be divided into foam sandwich board equipment and rock wool sandwich board equipment. This type of equipment plays a crucial role in the construction industry, producing sandwich panel products that combine excellent properties such as lightweight, high strength, insulation, thermal insulation, and fire resistance, making them the preferred building materials for modern industrial construction, cold chain logistics, clean engineering, and other fields.

The foam sandwich board machine is usually composed of multiple functional modules, including feeding system, forming unit, gluing device, composite mechanism, cutting unit and stacking equipment. These modules operate in coordination through a precise synchronous control system, forming a continuous production line. The core technical indicators of the equipment include production line speed, product width, thickness range, and degree of automation. At present, the advanced foam sandwich panel machine in the market has realized fully automated production, with a daily output of 800-1200 square meters. Some high-end models are even equipped with remote monitoring and fault diagnosis systems, greatly reducing the operation difficulty and maintenance costs.

From the application field, the products produced by foam sandwich panel machines are widely used in various architectural scenes. In the industrial field, it is used for the construction of roofs and walls in factories and warehouses; In the cold chain industry, it is used for the manufacturing of cold storage panels and refrigerated compartment panels; In special environments, it is applied to places such as purification workshops and explosion-proof compartments. Different application scenarios have different requirements for plate performance, which also promotes the development of foam sandwich board machines in the direction of diversification and specialization, and can produce products that meet various special needs.

According to its structural characteristics, applicable core materials and production process, foam sandwich panel machines can be divided into many types, each of which has its unique advantages and application scenarios. Understanding these classifications helps production companies choose suitable equipment based on their product positioning and market demand.

According to the type of core material, foam sandwich panel machines are mainly divided into polyurethane (PU/PIR) sandwich panel production line, rock wool sandwich panel production line and dual-use composite equipment. The polyurethane sandwich panel production line is specialized in the production of composite panels with polyurethane foam as the core layer. Such equipment is usually equipped with a precise foaming system, which can directly inject polyurethane raw materials between two layers of metal plates and form them through chemical reaction foaming. Polyurethane core material has an extremely low thermal conductivity (about 0.022W/(m · K)) and excellent insulation performance, making it particularly suitable for places with strict insulation requirements such as cold storage. The rock wool sandwich panel production line is specifically used to produce sandwich panels with rock wool as the insulation layer. This type of equipment emphasizes the precise paving and edge sealing of rock wool, and the fire resistance of the produced panels can reach Class A. It is widely used in public buildings and industrial facilities with high fire protection requirements. The dual-use composite equipment has multiple functions and can switch between producing sandwich panels with different core materials through simple adjustments, providing users with greater production flexibility.

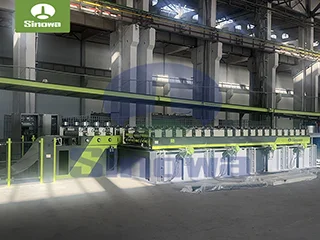

According to the degree of automation, foam sandwich board machines can be divided into full-automatic, semi-automatic and manual models. The fully automatic models represent the highest level in the industry, such as the polyurethane color steel sandwich panel production line produced by Sinowa Company, which adopts a PLC control system to achieve full process automation from coil unwinding to finished product stacking. Only 1-2 operators are needed to complete the production. These types of equipment are usually equipped with precision servo drive systems, automatic correction devices, and computer-controlled cutting units. The production speed can reach 4-6 meters/minute, and the product size accuracy can be as high as ± 0.5mm. Semi automatic models require a lot of manual intervention, such as manual assistance for alignment in composite processes and manual measurement in cutting processes. However, the equipment investment cost is relatively low and suitable for small and medium-sized production enterprises. Manual models rely mainly on manual operation, with low production efficiency, and have gradually been phased out by the market.

According to the production process, foam sandwich board machines mainly include continuous and intermittent types. Continuous production lines such as Sinowa's PU/rock wool color steel sandwich panel fully automatic production line, where raw materials enter from one end and undergo continuous rolling, lamination, curing, cutting and other processes to form complete sandwich panel products. This process has high production efficiency, stable product quality, and is suitable for large-scale standardized production. Intermittent equipment adopts a segmented production method, such as first producing the upper and lower panels, and then bonding or pouring them with the core material. This process has high flexibility and is suitable for the production needs of small batches and multiple varieties, but the production efficiency is relatively low.

In addition, there are some special foam sandwich board machines, such as special production lines for refrigerated carriage boards, special equipment for purification boards, etc. These devices have been specifically optimized for specific application scenarios, such as the refrigerated truck production line strengthening the strength and airtightness requirements of the board, while the purification board equipment focuses on the flatness and antibacterial performance of the board surface.

As the core equipment of composite panel production, foam sandwich panel machine's working principle is based on the organic combination of precision mechanical transmission, material composition and automatic control technology. The entire production line coordinates the operation of multiple functional modules, processes metal coils and core materials through a series of processing steps, and finally outputs sandwich panel products that meet the requirements.

The typical workflow of the foam sandwich board machine starts from the uncoiling and leveling of the metal coil. The metal coil (usually color coated steel plate or aluminum coil) is installed on the feeding rack, unfolded by the unwinding device, and then enters the leveling machine to eliminate curling stress and ensure the flatness of the plate. Subsequently, the flat metal plate enters the forming unit and is formed into the desired cross-sectional shape through multiple passes of roller pressing. This process is extremely critical, as the quality of the molding directly affects the appearance and mechanical properties of the final product. During the molding process, the feeding system on the other side applies the same treatment to the lower metal plate.

The next step is the gluing process, where the system evenly applies the prepared adhesive to the contact surface between the metal plate and the core material. There are various ways to apply glue, and high-end equipment uses computer-controlled spraying systems to accurately control the distribution of glue amount; Economical equipment may use roller coating or scraping methods. After the adhesive coating is completed, the equipment enters the core composite stage. Core layer materials (polyurethane foam, rock wool or other thermal insulation materials) are accurately sent between the upper and lower metal plates, and appropriate pressure is applied through the extrusion device to make the three closely combined. For polyurethane sandwich panels, this process is more complex, requiring direct injection of mixed polyurethane raw materials between metal panels. The raw materials foam and expand in a closed space, filling the entire cavity and forming a strong bond with the metal panels.

The composite board enters the curing zone and the adhesive or foam material is completely cured under controlled temperature environment. The curing time varies depending on the material, polyurethane usually takes a few minutes, while some structural adhesives may require longer times. After solidification is completed, the board is sent to the cutting area and precision cut by a high-speed sawing machine according to the set length. Finally, the finished boards are automatically stacked by the stacking device to complete the entire production process.

Related

Thermal Insulation Decorative Sandwich Panel Machine

PU Sandwich Panel Machine Manufacturer From China

Sandwich Panel Line For Cold Storage

PIR Insulated Sandwich Panel Machine

Cold Room Panel Production Line

PU Sandwich Panel Continuous Production Line

PU Isolation Board Production Line

Wall PU Sandwich Panel Machine

Clean Room Sandwich Panel Machine

Exterior Wall PU Sandwich Panel Machine