Composite Rock Wool Sandwich Panel Equipment

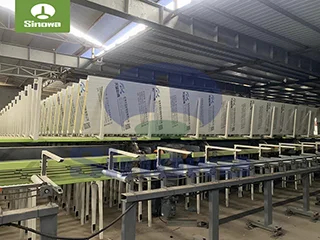

Composite rock wool sandwich panel equipment is a professional mechanical device used for producing rock wool sandwich panels. It combines color steel plates with rock wool core materials into a whole through an automated assembly line. Unlike traditional on-site composite methods, modern automation equipment can achieve standardized and efficient production of rock wool sandwich panels in factory environments, greatly improving product quality and consistency.

Composite rock wool sandwich panel equipment usually consists of multiple functional modules, including feeding system, glue coating device, composite mechanism, cutting unit, and stacking system. According to the degree of automation, equipment can be divided into two types: semi-automatic and fully automatic. Semi automatic equipment has a relatively low price, but its production efficiency is not high, making it suitable for small businesses or start-up factories; Although the investment in a fully automated production line is relatively large, the daily output can reach 800-1200 square meters, and the product quality is more stable, suitable for medium to large-scale production needs. From the perspective of technological development, there are several obvious trends in composite rock wool sandwich panel equipment: intelligent control systems are becoming increasingly popular, and PLC and human-machine interface have become standard equipment; Enhanced multifunctionality of the device, with one host compatible with producing multiple types of sandwich panels; The energy-saving and environmental protection characteristics are constantly improving, reducing energy consumption and material waste in the production process.

The core value of rock wool sandwich panel equipment lies in its ability to produce building materials with excellent fire resistance. Tests have shown that rock wool sandwich panels produced with high-quality equipment can withstand high temperatures of over 1000 ° C and meet the strictest building fire protection standards. At the same time, the precision of the equipment ensures a strong bond between the rock wool core material and the steel plate, making the final product have good thermal insulation performance and structural strength, making it an ideal choice for modern industrial plants, storage facilities, clean workshops and other buildings.

As a precision and complex production system, the core structure of the composite rock wool sandwich panel equipment consists of three functional modules working together to form an efficient and continuous production line. A deep understanding of the design principles and working mechanisms of these modules is of great significance for equipment operation, maintenance, and troubleshooting.

The gluing system is the first critical process to ensure product quality. Modern equipment typically uses enclosed glue storage tanks, equipped with transparent observation windows and dust covers, which ensure the cleanliness of the glue and facilitate real-time monitoring of the glue volume. The adhesive solution is transported to a specially designed sponge application pad or spray tube through a high-precision metering pump to achieve uniform distribution of the adhesive. The advanced coating system adopts a "through-hole coating tube" design, which achieves atomized spraying of the adhesive liquid through hundreds of micropores, saving 15-20% of adhesive usage compared to traditional rolling coating methods. The innovative design of the observation film device enables operators to visually inspect the uniformity of glue application, timely detect and solve possible problems such as hole blockage or uneven glue volume. The thickness of the adhesive coating is usually controlled within the range of 0.3-0.5mm. If it is too thin, it will affect the bonding strength, while if it is too thick, it will cause the adhesive to overflow, affecting the appearance and increasing the cost.

The extrusion device is a key link in tightly bonding the materials of each layer. This module adopts a spring-loaded pressure roller structure, and the first buffer spring can automatically adjust the pressure according to the material thickness, ensuring that different specifications of products can achieve the best composite effect. The surface of the pressure roller is usually processed with special textures, and the friction coefficient is increased by more than 40% compared to traditional smooth rollers, effectively preventing material slippage. In the production of rock wool sandwich panels, special attention needs to be paid to the coordination of temperature and pressure in the extrusion process. The working temperature is generally maintained between 60-80 ℃, and the pressure is controlled within the range of 0.3-0.5MPa. This can activate the viscosity of the adhesive without damaging the porous structure of the rock wool. The latest model of equipment has added an infrared preheating device in the extrusion area, which can soften the PE coating on the surface of the color steel plate in advance, further improving the bonding strength.

Cutting and collecting components are the final stages of the production line, directly affecting product yield and appearance quality. Vertical cutting uses a high-speed circular saw with a cutting speed of up to 30-50 meters per minute. The saw blade diameter is usually 400-500mm and the thickness is 2.5-3.5mm. It is made of hard alloy material to ensure the flatness of the cutting surface. Horizontal cutting uses reciprocating saws or band saws to automatically complete cutting to a predetermined length. The collection area adopts a linkage mechanism between the second buffer spring and the clamping plate, which absorbs the impact force when the sheet falls through a hydraulic damping system, ensuring that the cut sheet can be stacked smoothly without causing corner damage. Industry data from 2024 shows that equipment equipped with advanced collection systems can control the breakage rate of sheet metal below 0.3%, reducing losses by 85% compared to traditional collection methods.

The working principle of the composite rock wool sandwich panel equipment reflects the precise coordination of mechatronics integration. Starting from the release of colored steel plates from the uncoiler, the entire production process is fully automated under the control of a PLC system, including surface cleaning, gluing, rock wool paving, composite pressing, cutting to length, and automatic stacking. Operators only need to set product parameters (such as length, thickness, etc.) through the human-machine interface, and the equipment can automatically adjust the working status of each section to ensure the production of high-quality rock wool sandwich panels that meet standards. This continuous production mode not only has high efficiency, but also stable product quality, which is incomparable to traditional manual production methods.

The production process of composite rock wool sandwich panels is a precision technology that integrates material science and mechanical engineering, and each process directly affects the performance indicators of the final product. Modern production processes constantly pursue higher production efficiency and lower energy consumption while ensuring product quality, reflecting the progress and innovation of industrial manufacturing.

The fully automated assembly line production process represents the most advanced production method currently available. The process flow begins with the unwinding and leveling of the color steel coil, eliminating the stress generated during the curling process of the steel plate through a precision roller group, ensuring that the flatness error of the substrate does not exceed 0.5mm/m. Subsequently, it enters the core composite stage, where the upper steel plate is subjected to electrostatic dust removal before entering the adhesive coating area. A serrated scraper is used to evenly apply polyurethane adhesive, with the coating amount strictly controlled within the range of 180-220g/m ². At the same time, the rock wool core material is automatically divided and rotated 90 degrees to make the fiber direction perpendicular to the board surface, which can significantly improve the compressive strength of the product. In the composite zone, the upper and lower steel plates are bonded to the rock wool core material under a pressure of 0.4-0.6MPa, with a typical bonding speed of 5-8 meters per minute and a temperature controlled at 70 ± 5 ℃ to achieve the best bonding effect.

The precise control of key production parameters is the foundation for ensuring product quality. The density requirement for rock wool core material is 120-150kg/m ³. A low density will affect the sound insulation and fire resistance performance, while a high density will increase costs and be unfavorable for construction. The thickness of color steel plate is generally between 0.4-0.8mm, and the commonly used aluminum zinc steel plate AZ150 (zinc aluminum magnesium coating 150g/m ²) has excellent corrosion resistance. The common thicknesses of sandwich panels produced by equipment are 50mm, 75mm, 100mm, and 150mm, with widths of 950mm or 1150mm. The length can be customized according to customer needs, but generally does not exceed 12 meters for transportation. The temperature and humidity of the production environment should also be controlled within a certain range. The ideal conditions are a temperature of 15-30 ℃ and a relative humidity of no more than 70%. Excessive humidity can affect the curing speed of the adhesive.

Choosing the appropriate composite rock wool sandwich panel machine is a decision-making process that requires comprehensive consideration of multiple factors, which directly affects the return on investment, product quality, and long-term development of the enterprise. Faced with the dazzling array of equipment models and supplier promotions in the market, buyers need to establish a scientific evaluation system in order to make wise choices.

Related

Foam Rock Wool Board Production Line

Rockwool Roof Panel Production Line

Color Steel Rock Wool Board Plant

PU Side Sealing Rock Wool Sandwich Panel Production Line

Systems For Rock Wool Production

Mineral Wool Steel Sandwich Panel Production Line

Mineral Wool Panel Making Machine

Rock Wool Board Production Line

Color Steel Rock Wool Sandwich Panel Machine

Mineral Wool Sandwich Panel Making Machine