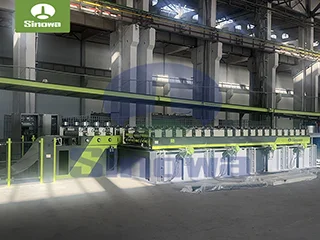

Sandwich Panel Foam Making Machine

The Sandwich Panel Foam Making Machine is an efficient and automated production equipment mainly used for producing various foam sandwich panels.

The working principle of the Sandwich Panel Foam Making Machine mainly includes the following steps:

Raw material preparation: Prepare liquid raw materials (such as polyurethane, polystyrene, etc.) in a certain proportion and ensure that the quality of the raw materials meets production requirements.

Mixing and foaming: Send liquid raw materials into a mixer and stir evenly, then foam them through a foaming machine. The foaming machine rapidly foams the raw materials by heating and increasing the pressure to form foam with micro closed cell structure.

Molding and curing: Send the foamed raw materials into the mold for molding and curing. In the mold, the raw materials undergo certain pressure and temperature effects to form sandwich panels with certain strength and stiffness.

Trimming and packaging: The sandwich panel taken out of the mold is trimmed and cut to achieve the desired size and shape. Finally, package and label the finished product for storage and transportation.

Foam sandwich panels have the advantages of lightweight, high strength, thermal insulation, sound insulation, fire resistance, etc., and are widely used in various fields:

Building materials industry: used to produce insulation materials for walls, roofs, floors, etc., to improve the energy-saving performance and comfort of buildings.

Furniture manufacturing industry: used to make filling materials for sofas, mattresses, and other furniture, improving the comfort and durability of furniture.

Automotive manufacturing industry: used for making car interiors, sound insulation materials, etc., reducing car weight, improving fuel economy and ride comfort.

Rail transit: used to make train floors, carriage linings, etc., which play a role in reducing weight, sound absorption, seismic isolation, and thermal insulation.

The foaming machine is the core component of the Sandwich Panel Foam Making Machine, and its performance directly affects the quality of the finished panels. Modern foaming machines adopt advanced technologies such as flow control technology, temperature control technology, self-cleaning gun head technology, high-speed shear mixing emulsification technology, etc., to ensure uniform mixing of raw materials and efficient foaming. In addition, with the promotion and application of high flame retardant materials, the new foaming machine is also equipped with the use technology of environmentally friendly foaming agents such as pentane to meet the market's demand for environmentally friendly products.

At present, Sandwich Panel Foam Making Machines have broad application prospects in the market. With the increasing demand for building energy efficiency, environmental protection, and comfort, the demand for foam sandwich panels as a high-quality insulation material will continue to grow. Meanwhile, with the continuous advancement of technology and the reduction of costs, the application scope of Sandwich Panel Foam Making Machines will also be further expanded. In the future, Sandwich Panel Foam Making Machines will pay more attention to the development direction of automation, intelligence, and environmental protection to meet the market's demand for high-quality, high-efficiency, and low-energy products.

The Sandwich Panel Foam Making Machine as an efficient and automated production equipment, has broad application prospects in various fields. With the continuous advancement of technology and the continuous development of the market, its application scope and performance will continue to improve and perfect.

Related

Sandwich Panel Forming Machine

Thermal Insulation Decorative Sandwich Panel Machine

PU Sandwich Panel Machine Manufacturer From China

Sandwich Panel Line For Cold Storage

PIR Insulated Sandwich Panel Machine

Cold Room Panel Production Line

PU Sandwich Panel Continuous Production Line

PU Isolation Board Production Line

Wall PU Sandwich Panel Machine

Clean Room Sandwich Panel Machine