PU Sandwich Panel Production Line For Warehouse Partition Panels

The polyurethane sandwich panel production line is an automated equipment system specialized in producing polyurethane composite panels for construction, designed specifically to meet the partition needs of modern storage facilities. This production line combines the metal panel (usually color steel plate or galvanized plate) with polyurethane foam core through continuous foaming process to form building panels with excellent thermal insulation, fire prevention and structural performance.

With the rapid development of the logistics industry and the increasing demand for modern warehousing facilities, polyurethane sandwich panels have become the preferred material for warehouse partitions due to their advantages of lightweight, high strength, thermal insulation, fire resistance, and easy installation, promoting the continuous upgrading and innovation of professional production equipment.

The main components of the polyurethane sandwich panel production line

Open book system

The uncoiling system is the starting point of the production line, mainly composed of the following equipment:

Dual station unwinding machine: achieving uninterrupted production, one station can prepare the next roll of material while the other is working

Automatic correction device: ensures precise alignment of metal coils when entering the production line

Pre treatment cleaning equipment: Remove oil stains and impurities from metal surfaces to improve bonding quality

Tension control system: maintain smooth transportation of the coil material to avoid deformation or wrinklingForming system

The forming system processes flat metal plates into the desired plate shape:

Multi pass roll forming machine: gradually forming the flat plate into the desired cross-sectional shape through 12-16 sets of roll forming units

Hydraulic shearing machine: Accurately cut the formed metal panel according to the set length

Online detector: Real time monitoring of forming size accuracy, automatic feedback adjustmentFoam composite system

The core foam composite process includes:

Two component high-pressure foaming machine: precise control of polyurethane raw material ratio and injection volume

Temperature control unit: maintain raw materials and molds at the optimal reaction temperature

Continuous laminating machine: Under pressure, polyurethane is fully foamed and cured between two layers of metal plates

Maturation zone: ensure that the foam is fully cured to achieve the best performanceCutting and Stacking System

After completing the post-processing of the board:

Flying saw cutting machine: high-speed and precise cutting, with smooth and burr free cuts

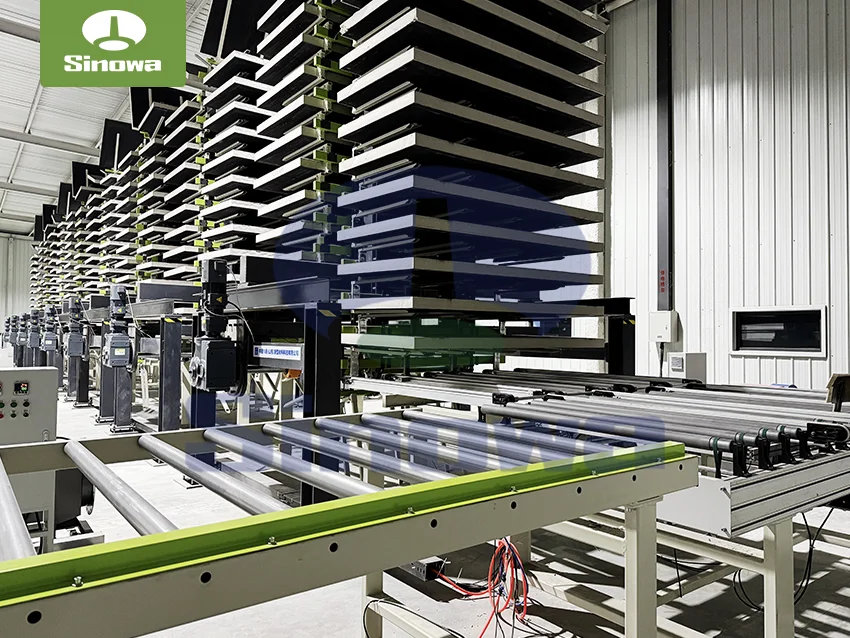

Automatic stacker crane: Automatically stack finished products according to preset programs

Packaging system: automatic lamination or packaging to protect the surface of the board

Production process flow

Metal plate pretreatment: uncoiling → cleaning → leveling → forming

Lower plate conveying: Accurately feed the formed lower plate into the laminating machine

Polyurethane foaming: raw material mixing → high-pressure injection → foaming and expansion between panels

Upper panel composite: precise alignment and coverage of the upper panel → pressure composite

Maturation and setting: control temperature and humidity to make foam completely solidified

Fixed length cutting: precise cutting according to order requirements

Automatic stacking: Classify, stack and package

The entire production process adopts PLC fully automatic control, with a production speed of up to 6-12 meters/minute. The length of the board can be customized according to demand, and the width is usually between 1000-1200mm, with a thickness range of 50-200mm.

Advantages of Storage Application of Polyurethane Sandwich Panels

Space optimization:

Lightweight characteristics (10-14kg/m ²) reduce structural loads and enable higher-level storage

Diverse thickness options for space separation to meet different insulation needsEnvironmental control:

Excellent thermal insulation performance (thermal conductivity of 0.022W/m · K) reduces temperature control energy consumption

The airtight structure effectively prevents moisture and dust, protecting stored itemsSecurity performance:

Flame retardant formula meets warehouse fire prevention requirements

High strength core material (compressive strength ≥ 150kPa) resistant to accidental impacts such as forkliftsConvenient construction:

Modular design for quick installation, significantly reducing warehouse renovation cycle

Dry operation without construction waste, does not affect warehouse operationsEconomy:

The comprehensive cost is lower than that of traditional brick and concrete partition walls

With a lifespan of over 25 years and extremely low maintenance costs

The modern pu sandwich panel production line integrates multiple advanced technologies:

Intelligent control system:

Adopting Industry 4.0 architecture to achieve remote monitoring and data analysis

Automatically adjust process parameters to ensure stable product quality under different climatic conditionsEnergy recovery technology:

Foam reaction heat recovery for board curing, saving more than 30% energy

The exhaust gas treatment system achieves VOCs emission standardsFlexible Production Design:

The rapid mold changing system can switch between different board types within 30 minutes

The same production line can produce products with multiple thicknesses and widths

When choosing a pu sandwich panel line, the following factors should be considered:

Capacity matching: Select appropriate specifications based on expected order volume to avoid overinvestment

Technological maturity: Prioritize selecting equipment and processes with successful cases

Scalability: Reserve upgrade space to accommodate future product upgrades

After sales service: Assessing the localization service capability of suppliers

Energy efficiency ratio: calculating long-term operating costs rather than just focusing on initial investment

As a key equipment in the construction of modern warehousing facilities, the pu sandwich panel manufacturing line is providing more efficient and environmentally friendly space separation solutions for the global logistics industry through continuous technological innovation and process optimization, and has become an important technical support for promoting the development of intelligent warehousing.

Related

Polyurethane Sandwich Panel Continuous Production Line

Polyurethane Flame Retardant Foam Sandwich Panel Machine

PU Sandwich Panels Plant

Edge Sealed PU Sandwich Panel Line

PU Sandwich Panel Line For Roof

Custom PU Sandwich Panel Line

Polyurethane Fireproof Sandwich Panel Machine

Automatic PU Sandwich Panel Line

Price of PU Sandwich Panel Machine

External Wall Insulation Board Assembly Line