PU Sandwich Panel Line For Roof

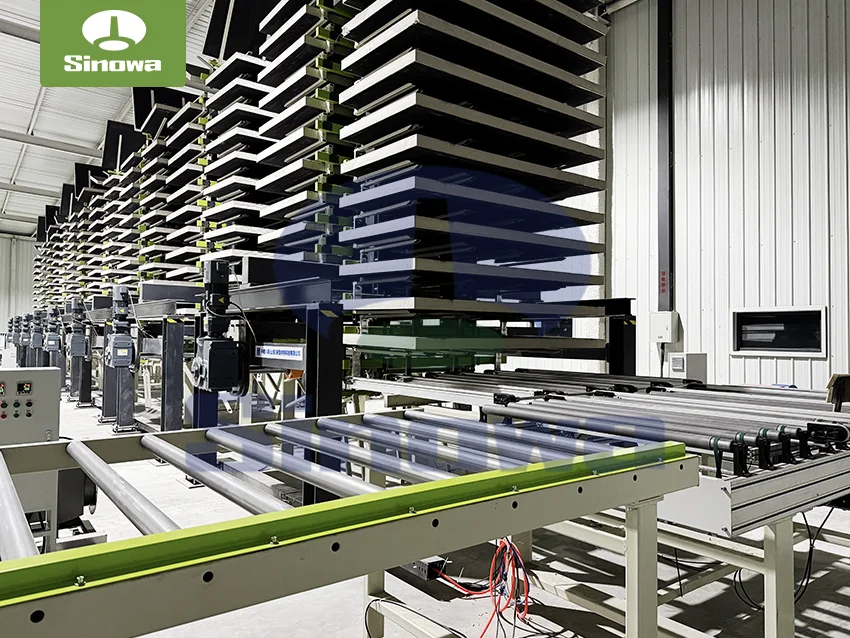

The pu sandwich panel production line for roofs is a specialized equipment line for producing polyurethane sandwich panels suitable for roof structures. This production line typically integrates advanced manufacturing technology and automation control systems to ensure efficient and precise production of polyurethane sandwich panels that meet quality standards.

Characteristic

Highly automated:

The pu sandwich panel line for roofs adopts an integrated linkage system to achieve fully automatic integrated control of the entire production line.

The modular design of the control system facilitates maintenance and upgrades.Flexible configuration:

The production line can be designed with multiple configurations according to customer needs to meet the production needs of polyurethane sandwich panels of different specifications and types.

By simple switching, sandwich panels of different thicknesses, widths, and lengths can be easily produced.Efficient and energy-saving:

Adopting advanced energy-saving design to reduce energy consumption and improve production efficiency.

The production line operates at a fast speed and can achieve a high output rate.Quality Assurance:

Key components are processed using CNC machine tools to ensure accuracy and quality.

The production line undergoes strict quality inspection and testing to ensure that the produced polyurethane sandwich panels meet relevant standards.

The pu sandwich panel line for roofs usually consists of the following parts:

Raw material preparation system: used for storing and transporting raw materials required for production, such as polyurethane raw materials, core materials, panels, etc.

Molding system: Process raw materials into the desired sandwich panel shape through molds and molding equipment.

Foaming system: Inject polyurethane raw materials into the mold and foam through chemical reactions to form the core layer of the sandwich panel.

Cutting system: Cut the formed sandwich panels to meet the requirements of different sizes.

Packaging system: Packaging the cut sandwich panels for transportation and storage.

Polyurethane sandwich panels for roofs are widely used in the roof structures of various buildings due to their excellent insulation, thermal insulation, fire resistance, and lightweight and high-strength properties. Especially in cold regions where good insulation performance is required, polyurethane sandwich panels have become an ideal roofing material.

At present, there are multiple professional manufacturers at home and abroad providing production lines for polyurethane sandwich panels for roofs. These manufacturers usually have rich production experience and advanced technical strength, and can provide customized production line solutions for customers. When choosing a production line, customers should fully consider factors such as performance, price, and after-sales service to ensure the selection of the most suitable production line for their needs.

The pu sandwich panel line for roofs is an efficient, flexible, and energy-saving production equipment that can meet the needs of different customers and produce high-quality polyurethane sandwich panels. With the continuous development of the construction industry and the increasing demand for insulation materials, the market prospects for polyurethane sandwich panel production lines for roofs are broad.

Related

PIR Sandwich Panel Machinery

Composite PU Sandwich Panel Line

Simple Maintenance Sandwich Panel Line

Professional Sandwich Panel Line

Automatic Steel Structure Sandwich Panel Production Line

Roof Sandwich Panel Machine

Sandwich Panel Manufacturing Plant

Sandwich Duct Panel Machine

Easy Maintainable PU Sandwich Panel Production Line

Roof Wall Sandwich Panel Making Machine