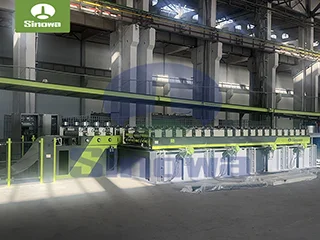

PIR Sandwich Panel Manufacturing Line For Thermal Insulation Boards

Polyisocyanurate (PIR) sandwich panels have emerged as a cornerstone in modern thermal insulation solutions, celebrated for their exceptional performance, durability, and versatility across diverse construction and industrial applications. The manufacturing line responsible for producing these high-quality insulation boards is a sophisticated integration of precision machinery, advanced material science, and rigorous process control, designed to consistently deliver panels that meet the evolving demands of energy efficiency and safety standards. Unlike traditional insulation materials, PIR sandwich panels feature a composite structure with a rigid PIR foam core bonded between two protective facings, typically metal sheets, creating a product that combines superior thermal insulation, structural stability, and fire resistance in a single, lightweight component. The manufacturing process of these panels is a continuous, streamlined operation that encompasses several key stages, each contributing to the final product’s performance and reliability.

The foundation of a high-performance PIR sandwich panel manufacturing line lies in the careful preparation and handling of raw materials, as the quality of inputs directly impacts the structural integrity and thermal properties of the finished panels. The core raw materials include isocyanates, polyols, catalysts, blowing agents, and additives, which react to form the rigid PIR foam, along with the facing materials that provide protection and structural support. Isocyanates and polyols are the primary components of the foam matrix, with their chemical composition and ratio carefully calibrated to achieve the desired density, thermal conductivity, and mechanical strength. Catalysts play a critical role in regulating the reaction rate of these components, ensuring that the foam cures uniformly and adheres effectively to the facings. Blowing agents are responsible for creating the closed-cell structure of the PIR foam, a key feature that minimizes thermal conductivity and prevents moisture absorption. Modern manufacturing lines prioritize the use of blowing agents that are environmentally friendly, avoiding substances that contribute to ozone depletion or high global warming potential, aligning with sustainable production practices.

The facing materials, commonly metal sheets such as steel or aluminum, undergo their own preparation process before integration into the sandwich panel structure. These sheets are typically uncoated or pre-treated to enhance adhesion with the PIR foam core, ensuring a strong bond that resists delamination over time. The preparation stage may include cleaning to remove contaminants, such as oil or dust, that could compromise the bonding process. Some manufacturing lines also incorporate surface texturing or profiling of the facing sheets to improve mechanical grip with the foam and enhance the panel’s overall structural performance. The dimensions of the facing sheets are precisely cut to match the desired panel size, with automated machinery ensuring consistency and accuracy to minimize waste and optimize production efficiency. This attention to detail in raw material preparation sets the stage for a smooth manufacturing process and a final product that meets strict performance criteria.

The foam mixing and dispensing stage is a critical juncture in the PIR sandwich panel manufacturing process, where the chemical reaction to form the PIR foam core takes place. This stage utilizes high-precision mixing equipment that combines the isocyanates, polyols, catalysts, blowing agents, and additives in exact proportions. The mixing process must be rapid and thorough to ensure a homogeneous mixture, as any inconsistencies can lead to variations in foam density, thermal performance, and structural strength. The mixed foam is then dispensed onto one of the prepared facing sheets as it moves along the production line. The dispensing system is computer-controlled, allowing for precise regulation of the foam volume and distribution, ensuring that the core thickness is uniform across the entire panel. This uniformity is essential for maintaining consistent thermal insulation properties, as uneven foam distribution can create thermal bridges that reduce the panel’s energy efficiency.

Following foam dispensing, the second facing sheet is applied to the top of the foam core, forming the sandwich structure. This lamination process requires careful alignment of the two facing sheets to ensure that the panel edges are straight and the core is fully encapsulated. Once the sandwich structure is formed, it passes through a series of compression rollers that apply uniform pressure to the panel. This compression ensures that the foam core adheres tightly to both facing sheets, eliminates any trapped air pockets, and shapes the panel to the desired thickness and flatness. The pressure applied during this stage is carefully calibrated based on the foam’s curing characteristics, as excessive pressure can compress the foam too much, reducing its insulation properties, while insufficient pressure may result in poor bonding between the core and facings. The compression rollers are equipped with temperature control features to assist in the foam curing process, accelerating the chemical reaction and ensuring that the panel retains its shape and structural integrity.

Curing is a vital stage in the manufacturing process, as it allows the PIR foam to fully harden and develop its final mechanical and thermal properties. The curing process typically takes place in a controlled environment, such as a heated tunnel or chamber, where temperature and humidity are closely monitored. The optimal curing temperature varies depending on the foam formulation but is generally maintained at a level that accelerates the cross-linking of the polymer chains without compromising the foam’s structure. The duration of curing is determined by the foam’s reaction kinetics, with modern manufacturing lines using sensors to monitor the foam’s hardness and cure state in real time. This real-time monitoring allows for adjustments to the curing time and temperature, ensuring that each panel is fully cured before moving to the next stage. Proper curing is essential for achieving the PIR foam’s characteristic high fire resistance, as under-cured foam may not perform as expected in fire conditions. Additionally, fully cured foam exhibits superior dimensional stability, preventing warping or deformation of the panels during storage, transport, or installation.

After curing, the continuous panel web is moved to the cutting station, where it is trimmed to the desired length and width using high-precision cutting equipment. The cutting process must be accurate to ensure that the panels meet the specified dimensions, as irregularities can complicate installation and reduce the overall efficiency of the insulation system. Modern manufacturing lines utilize computer numerical control (CNC) cutting machines that offer exceptional precision, minimizing waste and ensuring consistency across all panels. Some cutting stations also incorporate edge profiling capabilities, creating tongue-and-groove or other specialized edges that enhance the panel’s joint tightness when installed. Tight joints are critical for preventing air leakage and thermal bridges in the final insulation system, so the quality of edge profiling directly impacts the panel’s performance in real-world applications.

Quality control is an integral part of every stage of the PIR sandwich panel manufacturing line, ensuring that the finished products meet the required performance standards and are free from defects. Multiple quality checks are conducted throughout the process, starting with the inspection of raw materials to verify their chemical composition and purity. During foam mixing and dispensing, samples are regularly tested to measure foam density, cell structure, and thermal conductivity. These tests help identify any variations in the mixing process and allow for immediate adjustments to maintain product consistency. After curing, panels are inspected for dimensional accuracy, flatness, and bonding strength between the core and facings. Bonding strength tests may involve shear or peel tests to ensure that the foam core does not separate from the facings under mechanical stress. Additionally, visual inspections are conducted to check for surface defects, such as dents, scratches, or foam irregularities, which could affect the panel’s aesthetics or performance.

Advanced manufacturing lines may also incorporate non-destructive testing methods to evaluate the internal structure of the panels without damaging them. These methods can detect hidden defects, such as voids or uneven foam distribution, that may not be visible during visual inspections. The results of all quality control tests are recorded and analyzed to identify trends and areas for process improvement. This data-driven approach to quality control helps manufacturers optimize their production processes, reduce waste, and consistently deliver high-quality panels. Panels that fail to meet the quality standards are either reworked if possible or discarded, ensuring that only qualified products reach the market.

The performance characteristics of PIR sandwich panels, which are directly influenced by the manufacturing process, make them an ideal choice for a wide range of applications. One of the most notable advantages of PIR sandwich panels is their exceptional thermal insulation performance, attributed to the closed-cell structure of the foam core. The low thermal conductivity of PIR foam means that thinner panels can achieve the same insulation efficiency as thicker panels made from traditional materials, optimizing usable space in buildings and reducing material usage. This thermal efficiency translates to significant energy savings for buildings, as it reduces the need for heating and cooling systems to maintain comfortable indoor temperatures. In industrial settings, such as cold storage facilities, PIR sandwich panels are particularly valuable, as they help maintain stable low temperatures with minimal energy consumption, preserving the quality of perishable goods.

Fire resistance is another key performance attribute of PIR sandwich panels, making them suitable for applications where safety is a top priority. The chemical structure of PIR foam, which contains a high degree of aromaticity, provides inherent fire resistance properties. When exposed to fire, PIR foam undergoes carbonization, forming a protective char layer that limits flame spread and prevents the foam from melting or dripping. This char layer helps maintain the panel’s structural integrity for a longer period, allowing for safe evacuation and minimizing property damage. The combination of fire resistance and thermal insulation makes PIR sandwich panels a preferred choice for commercial buildings, industrial facilities, and public spaces where fire safety regulations are stringent.

Structural stability and durability are also important characteristics of PIR sandwich panels, thanks to the strong bond between the foam core and facing materials. The composite structure provides high rigidity and compressive strength, allowing the panels to withstand mechanical stress, such as wind loads or structural weight, without deformation. Additionally, PIR foam is non-hygroscopic, meaning it does not absorb moisture, which prevents degradation of the panel’s performance over time. Moisture absorption can lead to mold growth, structural weakening, and reduced thermal insulation efficiency in other insulation materials, but PIR sandwich panels remain stable even in humid environments. This durability ensures a long service life for the panels, reducing the need for frequent replacement and lowering maintenance costs.

The versatility of PIR sandwich panels is further enhanced by the flexibility of the manufacturing line, which can produce panels of varying thicknesses, sizes, and facing materials to meet specific application requirements. For example, panels used in roofing applications may have thicker facings or specialized profiles to withstand weather conditions, while panels for interior partitions may be lighter and more flexible. The manufacturing line can also accommodate different facing materials, such as aluminum for corrosive environments or pre-painted steel for aesthetic purposes. This flexibility allows PIR sandwich panels to be used in a wide range of projects, including industrial warehouses, commercial malls, cold storage facilities, agricultural buildings, and residential constructions. In addition to building applications, PIR sandwich panels are also used in transportation, such as in the insulation of refrigerated trucks and shipping containers, where lightweight and efficient insulation is essential.

Sustainability has become an increasingly important consideration in the manufacturing industry, and PIR sandwich panel production lines are evolving to meet these demands. The inherent energy efficiency of PIR panels contributes to sustainability by reducing the carbon footprint of buildings over their lifecycle. Additionally, modern manufacturing processes prioritize the use of environmentally friendly raw materials and blowing agents, minimizing the environmental impact of production. The metal facings of PIR sandwich panels are highly recyclable, and efforts are being made to develop recycling methods for the PIR foam core, further enhancing the product’s sustainability. Some manufacturing lines also implement energy-efficient technologies, such as waste heat recovery systems, to reduce energy consumption during production. These sustainable practices not only benefit the environment but also align with the growing demand for green building materials in the construction industry.

The operation of a PIR sandwich panel manufacturing line requires a skilled workforce trained in the operation of precision machinery, chemical processes, and quality control. Operators must have a thorough understanding of the foam formulation and reaction kinetics to make real-time adjustments to the manufacturing process. Maintenance personnel play a critical role in ensuring the smooth operation of the machinery, conducting regular inspections and repairs to prevent downtime. Additionally, quality control technicians are responsible for conducting rigorous tests and analyzing data to maintain product consistency and performance. Continuous training and professional development are essential for the workforce to keep up with advances in manufacturing technology and material science, ensuring that the production line remains efficient and capable of delivering high-quality panels.

Future advancements in PIR sandwich panel manufacturing lines are likely to focus on further improving efficiency, sustainability, and product performance. Innovations in foam formulation may lead to even lower thermal conductivity and higher fire resistance, while advances in machinery could increase production speed and precision. The integration of artificial intelligence and machine learning into the manufacturing process may enable predictive maintenance, reducing downtime and optimizing resource usage. Additionally, the development of more sustainable raw materials and recycling processes will continue to enhance the environmental profile of PIR sandwich panels. As the demand for energy-efficient and fire-safe insulation materials grows, the PIR sandwich panel manufacturing line will remain at the forefront of innovation, adapting to meet the changing needs of the construction and industrial sectors.

In conclusion, the PIR sandwich panel manufacturing line is a complex and sophisticated system that combines advanced material science, precision engineering, and rigorous quality control to produce high-performance thermal insulation boards. Each stage of the manufacturing process, from raw material preparation to cutting and quality inspection, is carefully designed to ensure that the finished panels exhibit exceptional thermal insulation, fire resistance, structural stability, and durability. The versatility of the manufacturing line allows for the production of panels tailored to a wide range of applications, while ongoing advancements in sustainability and technology continue to enhance the product’s environmental profile and performance. As the construction industry continues to prioritize energy efficiency and safety, PIR sandwich panels and their manufacturing lines will play an increasingly important role in shaping the buildings of the future, providing effective and sustainable insulation solutions for years to come.

Related

PU Sandwich Panel Manufacturing Machinery For Wall Panel Production

Thermal Insulation Decorative Sandwich Panel Machine

Energy-Efficient PU Sandwich Panel Making Line With Low Power Consumption

PU Sandwich Panel Machine With Auto Packer

PU Sandwich Panel Machine Manufacturer From China

PU Sandwich Panel Machine With Fire Retardant Foam Core

Sandwich Panel Line For Cold Storage

PUF Sandwich Panel Line With Automatic PU Mixing Head And Injection System

PIR Insulated Sandwich Panel Machine

PU Sandwich Panel Line For Fire-Proof Panels