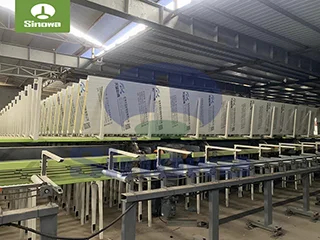

Composite Rock Wool Panel Machine

The composite rock wool panel machine is a specialized equipment used for producing composite rock wool boards. Composite rock wool board, as an efficient insulation material, has a wide range of applications in various fields such as construction, petroleum, power, metallurgy, etc.

The composite rock wool panel machine usually consists of feeding system, forming system, curing system, cutting system and other parts. The working principle is roughly as follows:

Feeding system: Feed raw materials (such as rock wool, resin glue, etc.) into the molding system.

Forming system: By using specific molds and processes, raw materials are processed into composite rock wool boards with specific shapes and sizes.

Curing system: Using heating or ultraviolet radiation to cure the resin adhesive and other adhesives in the composite rock wool board, thereby improving the strength and stability of the product.

Cutting system: Cut the cured composite rock wool board according to the required size.

Equipment features and advantages

Efficient and energy-saving: The composite rock wool board machine adopts advanced production technology and automation control system, which can significantly improve production efficiency while reducing energy consumption.

Easy to operate: The device is easy to operate and user-friendly. At the same time, the automation control system can monitor various parameters in the production process in real time to ensure stable product quality.

Strong adaptability: The composite rock wool board machine can produce composite rock wool boards of different specifications and thicknesses according to the needs of different customers, meeting the requirements of different application scenarios.

Environmental safety: The equipment generates less waste during the production process and is easy to handle. Meanwhile, the composite rock wool board produced with environmentally friendly materials has excellent insulation performance and environmental characteristics.

When choosing a composite rock wool panel machine, the following factors need to be considered:

Production demand: Select appropriate equipment models and specifications based on one's own production needs. For example, factors such as production scale, product specifications, and production efficiency need to be considered.

Equipment quality: Choose equipment with reliable quality and stable performance. Equipment quality can be evaluated by examining the qualifications of the equipment manufacturer, understanding the production process and raw material quality of the equipment.

After sales service: Choose equipment manufacturers that provide comprehensive after-sales service. Good after-sales service can ensure timely maintenance and upkeep of equipment during use, extending its service life.

Price factor: Consider the price factor while meeting production needs and equipment quality. You can choose the appropriate price level by comparing prices from different manufacturers and understanding market trends.

In order to ensure the normal operation and prolong the service life of the composite rock wool board machine, regular maintenance and upkeep are required. Specific measures include:

Cleaning equipment: Regularly clean the dust and debris on the surface of the equipment to keep it clean.

Inspect components: Regularly check whether each component of the equipment is intact, and replace them in a timely manner if there is any damage or wear.

Lubricating components: Regularly lubricate the components that require lubrication to ensure smooth operation of the equipment.

Calibration equipment: Regularly calibrate the equipment to ensure accurate size and stable quality of the produced composite rock wool board.

The composite rock wool panel machine, as an efficient, energy-saving, and environmentally friendly production equipment, has a wide range of application prospects in fields such as construction, petroleum, and electricity. In the process of selection and use, it is necessary to fully consider factors such as production demand, equipment quality, after-sales service, and price, and carry out regular maintenance and upkeep to ensure the normal operation of the equipment and extend its service life.

Related

Foam Rock Wool Board Production Line

Rockwool Roof Panel Production Line

Color Steel Rock Wool Board Plant

PU Side Sealing Rock Wool Sandwich Panel Production Line

Systems For Rock Wool Production

Mineral Wool Steel Sandwich Panel Production Line

Mineral Wool Panel Making Machine

Rock Wool Board Production Line

Color Steel Rock Wool Sandwich Panel Machine

Mineral Wool Sandwich Panel Making Machine