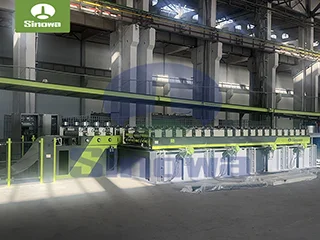

Color Steel Profiled Sandwich Panel Machine

The selection of color steel profiled sandwich panel machines should be comprehensively evaluated based on raw material supply (such as roll width), product specifications (such as fire rating), and production capacity requirements. It is recommended to conduct on-site inspections of the manufacturer's testing site.

Components of color steel profiled sandwich panel machine

Material release system: Double roll design (color steel roll width 1200mm), equipped with laser correction device and constant tension control, supporting the processing of color steel plates with a thickness of 0.3-0.8mm

Forming system: 14-20 rows of chrome plated alloy rollers, optimized waveform design, wave height tolerance ± 0.2mm, supporting quick mold change for overlapping corrugated

Composite host: 9 square tube spindles, 28 glue spindles, PLC controlled glue application amount, polyurethane high-pressure foaming system

Core technology

Equipped with Delta PLC+touch screen system, integrated with IoT remote monitoring module; Dynamic cutting system; Adaptive temperature control technology.

Core material compatibility: phenolic foam, rock wool, polyurethane

Fire protection requirements: rock wool line>polyurethane line>foam line

Customization requirement: The production of irregular plates requires the addition of a contour cutting module

The specific equipment configuration needs to be customized based on the color steel plate material and terminal product requirements.

Related

Sandwich Panel Forming Machine

Thermal Insulation Decorative Sandwich Panel Machine

PU Sandwich Panel Machine Manufacturer From China

Sandwich Panel Line For Cold Storage

PIR Insulated Sandwich Panel Machine

Cold Room Panel Production Line

PU Sandwich Panel Continuous Production Line

PU Isolation Board Production Line

Wall PU Sandwich Panel Machine

Clean Room Sandwich Panel Machine