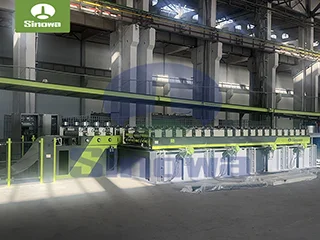

Automatic PU Sandwich Panel Machine

The automatic pu sandwich panel machine is an intelligent production equipment that integrates mechanical, electronic, and chemical technologies, specifically designed for continuous production of polyurethane (PU) sandwich panels. This equipment combines the metal panel (usually color steel plate or stainless steel) with polyurethane foam core through highly automated process to form building panels with excellent thermal insulation performance.

Compared with traditional manual production methods, fully automated pu sandwich panel production lines have significant advantages such as high production efficiency, stable product quality, low labor intensity, and high utilization of raw materials. A standard production line can produce 150-300 square meters of sandwich panels per hour, which is 10-15 times higher than manual production, and the product quality is uniform and consistent, fully meeting the strict requirements of modern construction industry for material performance.

The main components of an automatic pu sandwich panel machine

Open book system

The unwinding system is the starting point of the polyurethane sandwich panel production line, usually including:

Dual station unwinding machine: capable of non-stop roll changing and improving production efficiency

Automatic correction device: Ensure that the centering accuracy of the metal coil is within ± 1mm

Preprocessing unit: including cleaning, passivation and other processing techniques to enhance the bonding strength between the panel and the core materialForming system

The forming system is responsible for processing flat metal coils into the required plate shape:

Multi roll continuous forming machine: using 16-24 composition roller wheel progressive forming

Hydraulic servo system: precise control of forming pressure and speed

Quick mold changing device: capable of switching between different plate types within 30 minutesBubbler System

The core foaming system consists of the following units:

High pressure foaming machine: The working pressure is usually in the range of 120-200 bar

Temperature control unit: Accurately control the temperature of raw materials within ± 0.5 ℃ range

Mixing head: Adopting a self-cleaning design, the mixing efficiency reaches over 98%

Measurement system: Flow accuracy can reach ± 1.5%Composite system

The composite system achieves the perfect combination of panel and core material:

Double track press: pressure evenly adjustable (0.1-0.3MPa)

Temperature control platform: maintain the optimal foaming temperature environment

Online thickness gauge: Real time monitoring of sheet thickness (accuracy ± 0.2mm)Cutting system

The fully automatic cutting system includes:

Flying saw cutting unit: cutting accuracy ± 1mm

Automatic stacker crane: maximum stacking height can reach 2 meters

Waste recycling device: realizing automatic recycling and utilization of scrap materialsControl system

The intelligent control system is the brain of the polyurethane sandwich panel production line:

PLC+Industrial PC Dual Control System

Human Machine Interface (HMI) Operating Platform

Remote monitoring and fault diagnosis function

Production Data Automatic Collection and Analysis System

Core technical parameters of automatic pu sandwich panel machine

Production line speed: 3-12 meters/minute (adjustable)

Product width: 800-1200mm (standard), special specifications can be customized

Board thickness: 30-200mm

Panel thickness: 0.3-0.8mm

Density range: 35-60kg/m ³

Thermal conductivity: 0.018-0.024W/(m · K)

Compressive strength: ≥ 150kPa

Fire rating: up to B1 level (adjusted according to formula)

Production process flow of automatic pu sandwich panel machine

Panel pretreatment: uncoiling → cleaning → passivation → drying

Forming processing: forming the required plate shape through multiple roller presses

Injection foaming: precise measurement and injection of polyurethane mixture

Composite curing: foaming and bonding process completed under controlled environment

Fixed length cutting: automatically cut according to the set length

Finished product stacking: automatic stacking and packaging

Technical advantages and innovation points of automatic pu sandwich panel machine

Energy saving and environmentally friendly design:

Thermal energy recovery system can save 15-20% energy

Closed loop foaming process reduces VOC emissions

The waste recycling rate is over 95%Intelligent control system:

Adaptive PID Temperature Control Algorithm

Quality Inspection System Based on Machine Vision

Big data analysis optimizes production processesModular design:

Quick replacement mold system

Scalable production line configuration

Easy to maintain structural designAdvanced foaming technology:

High voltage impact mixing technology

Nano modified polyurethane formula

Low temperature foaming process

The products produced by automatic pu sandwich panel machines are widely used in:

Industrial plants and storage facilities

Cold storage and cold chain logistics center

Cleanrooms and pharmaceutical factories

Commercial buildings and mobile homes

Agricultural greenhouse and special buildings

Suggestions for the selection and maintenance of automatic pu sandwich panel machines

Selection considerations:

Capacity demand and product specifications

Equipment energy consumption and environmental indicators

Supplier's technical support capability

Equipment upgrade and expansion possibilitiesDaily maintenance points:

Regularly inspect the hydraulic and pneumatic systems

The foaming system is thoroughly cleaned every week

Quarterly electrical system testing

Annual comprehensive maintenance and calibrationOperator training:

Equipment operation specifications

Safety protection knowledge

Emergency handling of faults

Optimization of process parameters

With the continuous improvement of building energy-saving requirements and the rapid development of intelligent manufacturing technology, automatic pu sandwich panel machines are evolving towards higher efficiency, intelligence, and environmental friendliness, providing high-quality insulation solutions for the modern construction industry. Choosing appropriate production line equipment and mastering scientific operating methods will significantly enhance the market competitiveness and economic benefits of enterprises.

Related

External Wall Composite Insulation Board Production Line

Sandwich Panel Forming Machine

Thermal Insulation Decorative Sandwich Panel Machine

PU Sandwich Panel Machine Manufacturer From China

Sandwich Panel Line For Cold Storage

PIR Insulated Sandwich Panel Machine

Cold Room Panel Production Line

PU Sandwich Panel Continuous Production Line

PU Isolation Board Production Line

Wall PU Sandwich Panel Machine