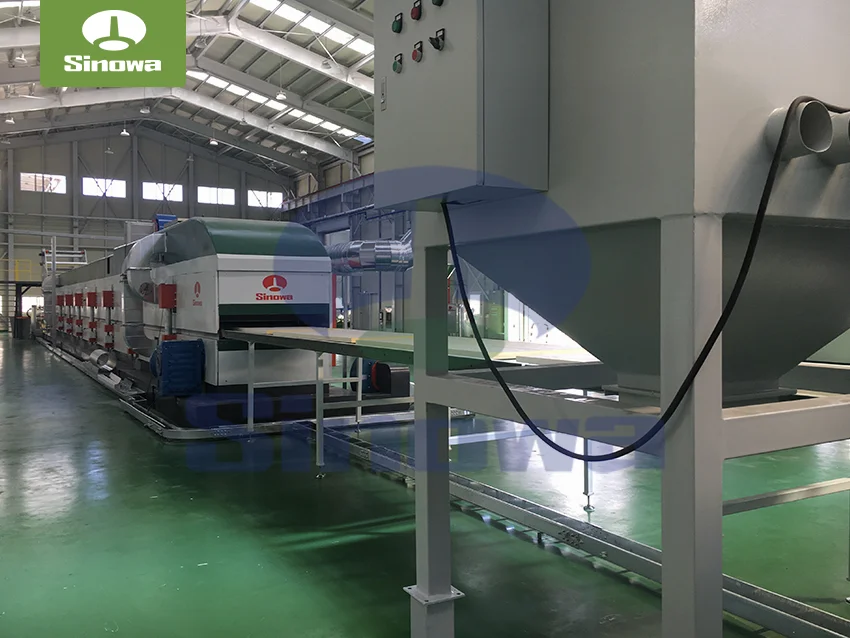

Automatic Insulation Board Production Line

The automatic insulation board production line is an industrial equipment used to manufacture energy-saving and environmentally friendly wall materials. With the continuous promotion and development of building energy conservation and green buildings, the automatic insulation board production line will become an important trend and direction in the future production of building wall materials.

Sinowa as a manufacturer of automatic insulation board production lines from China, has rich experience and advanced technology in the field of insulation board production lines, providing high-quality equipment and services to the market.

The raw materials for the automatic insulation board production line are diverse, including phosphogypsum, lightweight steel slag, fly ash, cement, river sand, sawdust, straw and other industrial and agricultural waste. These raw materials can be processed into various insulation boards such as inorganic permeable boards and silicon insulation boards.

The products of the automatic insulation board production line are widely used in fields such as building walls, roof insulation, cold storage, and road foundations. At the same time, these insulation boards are also suitable for insulation needs in special places such as refrigerated trucks, square floors, airports, etc.

The automatic insulation board production line adopts a dual drive roller extrusion process, which completes the entire board production process in one go through processes such as sizing, main material, laying, compounding, and re pressing. The equipment has a high degree of automation, runs smoothly, and the specifications can be adjusted freely.

Characteristics:

Energy saving and consumption reduction: The production line utilizes the heat released by chemical reactions to meet the production process requirements, without the need for high temperature and high pressure, reducing energy consumption.

Green and environmentally friendly: The production process has no noise and three waste emissions, which meets the requirements of modern society for environmental protection.

Efficient production: The high degree of equipment automation greatly reduces the labor intensity of production workers and improves production efficiency.

High quality product: The insulation board produced has a smooth and even surface, high density, lightweight seismic resistance, and superior fire and waterproof performance.

The external dimensions of the automatic insulation board production line are relatively large, and the equipment supports flexible adjustment of product specifications to meet the needs of different customers. The daily average production capacity of a single line is relatively high, and the specific production capacity is affected by various factors such as raw materials, equipment status, and operating technology.

The automatic insulation board production line has the characteristics of low investment and fast results. The production line adopts advanced production technology and equipment, which reduces production costs, improves product quality and competitiveness. At the same time, the production line also supports customized services, which can produce insulation boards of different specifications and performance according to customer needs, meeting the diverse needs of the market.

The promotion and application of automatic insulation board production lines can help to save resources and protect the ecological environment. The production line utilizes industrial waste and agricultural waste to produce insulation boards, achieving comprehensive utilization of resources and turning waste into treasure. Meanwhile, the widespread application of insulation boards helps to reduce energy consumption and carbon emissions in buildings, promoting the development of green buildings and sustainable industries.

Related

Foam PU Sandwich Panel Line

High-tech PU Sandwich Panel Line Manufacturer

PIR Sandwich Panel Line For Roof and Wall

Principle of Color Steel PU Sandwich Panel Machine

PIR Sandwich Panel Machinery

Composite PU Sandwich Panel Line

Simple Maintenance Sandwich Panel Line

Professional Sandwich Panel Line

Automatic Steel Structure Sandwich Panel Production Line

Roof Sandwich Panel Machine