Rockwool Sandwich Panel Production Line with Automatic Rock Wool Feeding System

Rockwool sandwich panels have become indispensable in modern construction and industrial applications due to their integrated advantages of fire resistance, thermal insulation, sound absorption and structural stability. The production line equipped with an automatic rock wool feeding system represents a leap forward in manufacturing efficiency and product consistency, transforming the traditional processing mode into a streamlined, precise and labor-saving operation. This integrated production system combines mechanical precision with intelligent material handling, ensuring that each panel meets the rigorous requirements of diverse application scenarios while optimizing resource utilization and production cycle. To fully understand the value of this production system, it is essential to explore its structural composition, core performance characteristics, diverse product types and extensive application fields.

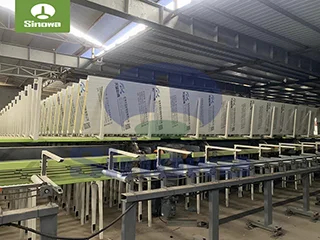

The structure of a rockwool sandwich panel production line with an automatic rock wool feeding system is a sophisticated assembly of interconnected modules, each performing a specific function to ensure the smooth progression from raw materials to finished products. At the heart of the system lies the automatic rock wool feeding module, which is designed to eliminate manual intervention and enhance material distribution accuracy. This module typically consists of storage hoppers, vibrating screening devices, weighing conveyors and precision feeding mechanisms. The storage hoppers are engineered to hold bulk rock wool materials in a dry, stable environment, preventing moisture absorption and material agglomeration. Vibrating screens remove impurities and oversized particles, ensuring that only qualified rock wool fibers enter the subsequent process. Weighing conveyors equipped with electronic sensing technology accurately measure the amount of rock wool fed into the production line, maintaining consistent core density across all panels. The precision feeding mechanism, often driven by servo motors, adjusts the feeding speed according to the production rhythm, ensuring uniform distribution of rock wool between the surface layers. This automatic feeding system not only reduces labor costs and human error but also enables real-time adjustment of material dosage, adapting to different panel thickness and density requirements.

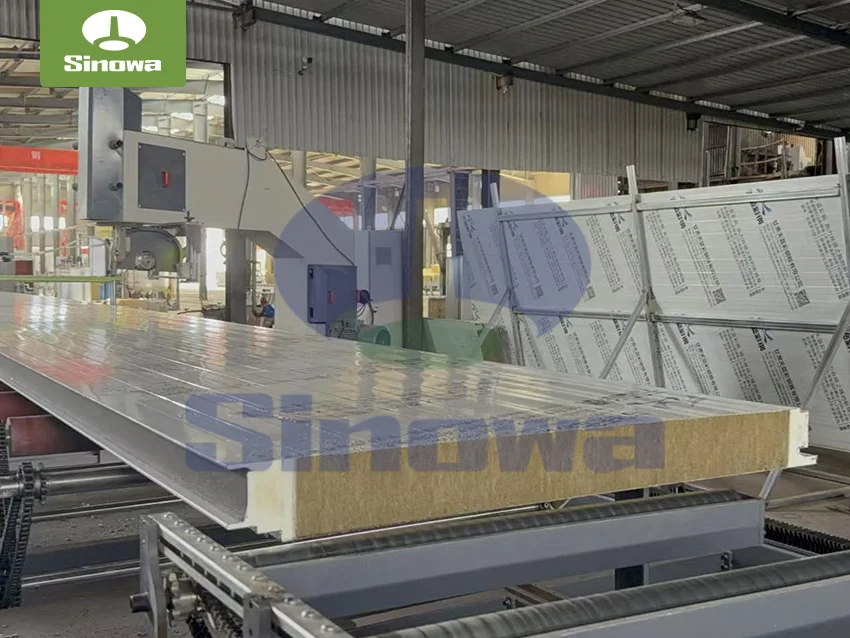

Beyond the automatic feeding system, the production line comprises several key functional sections. The surface layer forming module processes metal sheets—commonly galvanized steel, aluminum or color-coated steel—through roll forming technology. This module shapes the surface layers into desired profiles, such as corrugated, flat or embossed patterns, which enhance the structural rigidity and aesthetic appearance of the final panels. The bonding and compounding module is responsible for integrating the rock wool core with the surface layers. High-performance binders are evenly sprayed onto the surface of the rock wool and metal sheets, ensuring strong adhesion between the layers. A combination of pressure rollers and curing ovens then solidifies the bond, creating a unified structure where the rock wool core and surface layers work together to resist external forces. The cooling and cutting module follows, where the continuous panel sheet is cooled to room temperature to maintain dimensional stability before being cut into customized lengths by high-precision cutting machines. Waste edge recovery systems are also integrated into the production line, collecting and recycling excess materials to minimize waste and improve environmental sustainability. The entire structural design emphasizes modularity, allowing for easy maintenance, upgrade and adaptation to different production scales and product specifications.

The performance of rockwool sandwich panels produced by this advanced line is defined by the synergy between the automatic feeding system and the inherent properties of rock wool materials, resulting in products with exceptional comprehensive capabilities. Fire resistance stands out as one of the most prominent performance advantages. Rock wool, derived from molten basalt and other natural rocks, is inherently non-combustible, with a melting point exceeding 1000°C. The automatic feeding system ensures uniform distribution of the rock wool core, eliminating gaps that could compromise fire resistance. This uniform structure enables the panels to resist flame spread and heat transfer effectively, providing reliable fire protection for buildings and industrial facilities. The fire resistance duration can be adjusted according to panel thickness and density, catering to different safety requirements.

Thermal insulation performance is another key strength of these panels. The fibrous structure of rock wool traps air within its pores, creating a barrier that inhibits heat conduction. The automatic feeding system maintains consistent core density, ensuring stable thermal conductivity across the entire panel. Typical thermal conductivity values range from 0.036 to 0.044 W/(m·K) at different temperatures, making the panels highly effective in reducing energy consumption for heating and cooling. This performance is particularly valuable in buildings and facilities where temperature control is critical, such as cold storage, industrial workshops and commercial buildings. The combination of thermal insulation and structural stability also reduces the overall energy footprint of constructions, aligning with sustainable development goals.

Acoustic performance is enhanced by the porous structure of the rock wool core and the tight bonding between layers. The fibers absorb sound waves, reducing noise transmission between spaces and minimizing echo within enclosed areas. The automatic feeding system’s precise material distribution ensures that the rock wool core has a uniform density, avoiding acoustic weak points. This makes the panels ideal for applications requiring sound insulation, such as auditoriums, control rooms, data centers and residential buildings located in noisy environments. Additionally, the structural rigidity of the panels contributes to their acoustic performance by reducing vibration-induced noise.

Mechanical performance is optimized through the integrated production process. The bonding between the rock wool core and surface layers creates a composite structure with high rigidity and load-bearing capacity. The surface metal layers provide structural support, while the rock wool core enhances stability and resists deformation. The panels exhibit excellent compressive strength, shear strength and tensile strength, enabling them to withstand external forces such as wind, snow and structural loads. The automatic feeding system ensures that the rock wool core is evenly distributed, preventing uneven stress distribution and improving the overall mechanical stability of the panels. This allows for larger purlin spacing in construction, reducing the consumption of auxiliary structural materials and lowering construction costs. The panels also demonstrate good durability, with resistance to moisture, corrosion and aging, ensuring a long service life even in harsh environments.

Rockwool sandwich panels produced by lines with automatic feeding systems are available in a variety of types, categorized based on structural design, surface material, core density and application-specific modifications. Structural variations include single-groove wall panels, double-groove wall panels, hidden-screw wall panels and roof panels. Single-groove wall panels feature a simple tongue-and-groove design, facilitating quick installation and suitable for general exterior and interior walls. Double-groove panels have enhanced sealing performance, with foam-to-foam seals that improve airtightness and insulation, making them ideal for cold storage, clean rooms and pharmaceutical facilities. Hidden-screw wall panels have a sleek, aesthetic appearance with fasteners concealed within the panel joints, suitable for commercial buildings, showrooms and modular constructions where visual appeal is a priority. Roof panels are designed with corrugated or trapezoidal profiles to enhance water resistance and load-bearing capacity, adapting to the specific requirements of industrial sheds, prefabricated structures and large-span buildings.

Surface material variations cater to different environmental and functional needs. Galvanized steel surface layers offer excellent corrosion resistance, suitable for outdoor applications and industrial environments with high humidity. Color-coated steel layers provide a wide range of color options and enhanced weather resistance, combining aesthetics with durability. Aluminum surface layers are lightweight and corrosion-resistant, ideal for applications where weight reduction is important, such as modular buildings and ship hulls. Stainless steel surface layers are used in environments requiring hygiene and corrosion resistance, such as food processing plants and laboratories. The thickness of the surface layers can be adjusted between 0.3mm and 1mm, depending on the required mechanical strength and durability.

Core density variations allow for customization of performance characteristics. Low-density cores (80-100 kg/m³) prioritize thermal insulation and sound absorption, suitable for interior partitions and non-load-bearing walls. Medium-density cores (100-150 kg/m³) balance insulation performance with mechanical strength, suitable for general wall and roof applications. High-density cores (150 kg/m³ and above) offer enhanced mechanical performance and fire resistance, ideal for load-bearing structures, firewalls and industrial facilities with high safety requirements. Additionally, specialized rock wool cores, such as those with enhanced hydrophobicity (water repellency above 98%), are available for applications in humid environments, preventing moisture absorption and maintaining performance over time.

The applications of rockwool sandwich panels produced by these advanced production lines span across multiple industries, driven by their versatile performance and easy installation. In the construction industry, they are widely used for exterior walls, interior partitions, ceilings and roofs of industrial buildings, commercial complexes, residential buildings and public facilities. Industrial workshops and factories benefit from the panels’ fire resistance and thermal insulation, creating safe and energy-efficient working environments. Commercial buildings, such as shopping malls, office buildings and hotels, utilize the panels for their acoustic insulation and aesthetic flexibility, enhancing occupant comfort and reducing energy costs. Residential buildings employ the panels for interior partitions and exterior cladding, providing soundproofing and fire protection while optimizing energy efficiency.

Industrial and specialized applications further demonstrate the versatility of these panels. Cold storage facilities and refrigeration units rely on the panels’ excellent thermal insulation performance to maintain stable low temperatures, reducing energy consumption and ensuring the quality of stored goods. Clean rooms and laboratories require panels with high hygiene standards, corrosion resistance and airtightness, making double-groove and stainless steel-faced panels ideal choices. Data centers and control rooms utilize the panels’ acoustic and thermal insulation properties to maintain stable operating environments for sensitive equipment, reducing noise pollution and ensuring equipment reliability. Firewalls and fire-rated partitions in various buildings depend on the panels’ non-combustible properties and fire resistance duration to prevent the spread of fire, protecting lives and property.

Transportation and marine applications also benefit from the panels’ lightweight and durable characteristics. Modular buildings and prefabricated structures use the panels for quick assembly and transportation, reducing construction time and costs. Ship hulls and marine cabins employ aluminum-faced panels for corrosion resistance and weight reduction, ensuring safety and performance in marine environments. Tunnel linings utilize the panels’ fire resistance and sound absorption to enhance safety and comfort for commuters. Additionally, the panels are used in HVAC duct enclosures, compressor rooms and generator enclosures to reduce noise and improve thermal insulation, optimizing the performance of mechanical equipment.

The integration of automatic rock wool feeding systems into production lines has not only improved the quality and efficiency of rockwool sandwich panel manufacturing but also expanded their application scope. By ensuring consistent material distribution, reducing waste and enabling customization, these production systems meet the evolving demands of modern construction and industrial sectors. The panels’ combination of fire resistance, thermal insulation, acoustic performance and mechanical stability makes them a preferred choice for projects prioritizing safety, energy efficiency and sustainability. As the demand for high-performance, environmentally friendly building materials continues to grow, the rockwool sandwich panel production line with automatic feeding systems will play an increasingly important role in shaping the future of construction and industrial manufacturing. Ongoing technological advancements in material science and production automation are expected to further enhance the performance and versatility of these panels, opening up new application opportunities and contributing to more sustainable and resilient built environments.

Related

Environmental-friendly Rock Wool Board Production Line

Rock Wool Slab Production Equipment

Systems For Rock Wool Production

Mineral Wool Steel Sandwich Panel Production Line

Mineral Wool Panel Making Machine

Rock Wool Board Production Line

Color Steel Rock Wool Sandwich Panel Machine

Mineral Wool Sandwich Panel Making Machine

Automatic Rock Wool Panel Line

High Efficiency Rockwool Sandwich Panel Production Line Supplier