Rock Wool Sandwich Panel Making Machine with Heating and Cooling System

Rock wool sandwich panel making machines equipped with heating and cooling systems are integral pieces of equipment in the modern manufacturing industry, designed to produce high-quality rock wool sandwich panels that find extensive applications across various sectors. These machines combine advanced mechanical, electrical, and thermal control technologies to ensure the efficient and consistent production of panels with superior structural integrity and performance. Unlike basic panel making equipment, the integration of dedicated heating and cooling systems elevates the production process by enabling precise control over temperature-sensitive stages, which is crucial for optimizing the bonding, forming, and curing of the panels. The seamless coordination between the machine’s structural components and the thermal control systems ensures that each panel meets the required specifications, making these machines indispensable for businesses looking to produce reliable and durable rock wool sandwich panels on a large scale.

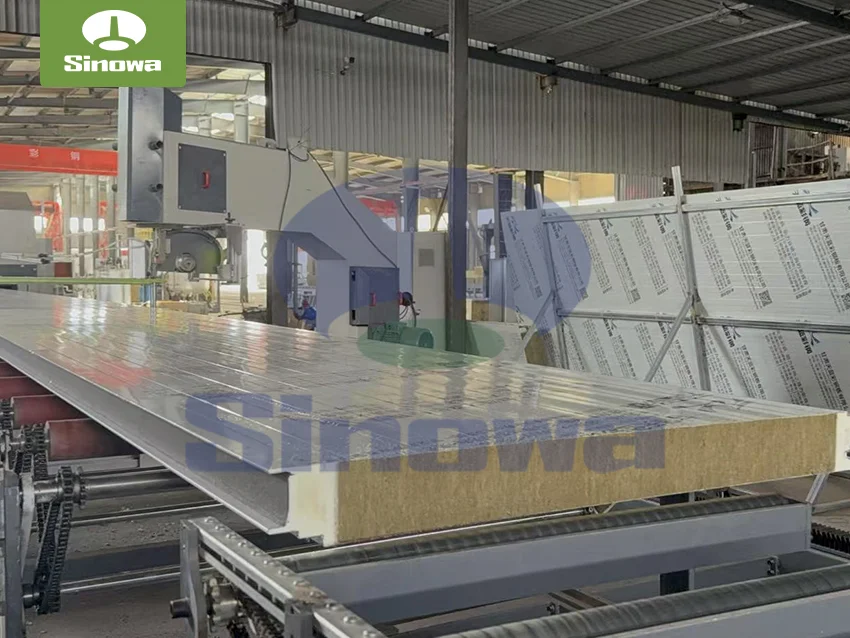

The structure of a rock wool sandwich panel making machine with heating and cooling system is a complex assembly of interconnected components, each playing a vital role in the overall production process. At the core of the machine is the feeding system, which is responsible for delivering raw materials to the subsequent processing stages in a consistent and controlled manner. This system typically includes conveyors, feeding hoppers, and dosage control mechanisms that regulate the flow of rock wool core materials, as well as the outer skin materials such as metal sheets or composite fabrics. The feeding system must be designed to handle different material densities and thicknesses, ensuring uniform distribution that forms the foundation of a high-quality sandwich panel. Following the feeding system is the forming unit, which shapes the raw materials into the desired panel configuration. This unit often consists of rollers, molds, or pressing plates that apply controlled pressure to the materials, ensuring that the rock wool core is securely bonded to the outer skins. The forming unit’s precision directly impacts the panel’s dimensions, flatness, and overall structural stability.

Integrated within the forming process are the heating and cooling systems, which are critical for achieving optimal material bonding and curing. The heating system is typically positioned before or during the forming stage, depending on the specific production requirements, and its primary function is to raise the temperature of the materials to a level that facilitates effective bonding. Rock wool core materials, when combined with adhesives or binding agents, require a specific temperature range to activate the bonding agents and ensure strong adhesion between the core and the outer skins. The heating system may utilize various heat sources, including electrical heating elements, hot air circulation, or infrared heating, each offering distinct advantages in terms of temperature control precision, energy efficiency, and heating speed. Electrical heating elements are often preferred for their ability to provide uniform heat distribution and precise temperature regulation, while hot air circulation systems are effective for heating larger surface areas evenly. The heating system is equipped with temperature sensors and control units that monitor and adjust the temperature in real time, preventing overheating which could damage the materials or underheating which would result in weak bonding.

After the forming and heating stages, the cooling system takes over to lower the temperature of the newly formed panels, allowing the bonding agents to cure and set properly. Rapid and uniform cooling is essential to maintain the panel’s shape, prevent warping or deformation, and ensure that the bond between the core and outer skins is fully stabilized. The cooling system may employ forced air cooling, water cooling, or a combination of both, depending on the production speed and material requirements. Forced air cooling systems use fans to circulate cool air over the surface of the panels, facilitating quick heat dissipation, while water cooling systems utilize cooled water pipes or jackets that come into contact with the panels, offering more efficient heat transfer for high-speed production lines. Similar to the heating system, the cooling system is equipped with temperature control mechanisms that ensure the panels are cooled to a specific temperature range before moving to the next stage of production, such as cutting or stacking. The coordination between the heating and cooling systems is crucial; the transition from heating to cooling must be seamless to avoid thermal shock, which could compromise the panel’s structural integrity.

Complementing these core components are the control system, cutting unit, and stacking system, which complete the production line. The control system serves as the “brain” of the machine, integrating all components and ensuring synchronized operation. It typically includes a programmable logic controller (PLC) and a human-machine interface (HMI) that allows operators to set and adjust production parameters such as temperature, pressure, feeding speed, and panel dimensions. The control system continuously collects data from sensors placed throughout the machine, making real-time adjustments to maintain consistent production quality. The cutting unit is responsible for trimming the continuous panel into individual panels of the desired length, using precision cutting tools such as circular saws or band saws that operate without stopping the production line, ensuring high efficiency. The stacking system then automatically collects and stacks the finished panels, reducing manual labor and minimizing the risk of damage to the panels during handling. All these components work together in harmony, forming a complete production system that can operate continuously for extended periods, meeting the high-volume production needs of various industries.

The performance of a rock wool sandwich panel making machine with heating and cooling system is evaluated based on several key metrics, including production efficiency, temperature control precision, panel quality consistency, energy efficiency, and operational stability. Production efficiency is a critical performance indicator, as it directly impacts the machine’s productivity and the overall cost-effectiveness of the production process. These machines are designed to operate continuously, with production speeds that can be adjusted according to the specific requirements of the panels being produced. The integration of heating and cooling systems allows for faster bonding and curing times, reducing the overall production cycle and increasing the number of panels produced per hour. Temperature control precision is another essential performance metric, as even minor fluctuations in temperature can significantly affect the quality of the panels. High-performance machines are equipped with advanced temperature control systems that can maintain temperatures within a narrow range, ensuring consistent bonding and curing across all panels. This precision also helps to reduce material waste, as panels produced with improper temperature control are often rejected due to weak bonding or structural defects.

Panel quality consistency is a direct reflection of the machine’s performance, encompassing factors such as panel thickness uniformity, bond strength, flatness, and dimensional accuracy. A high-performance machine will produce panels with consistent thickness across the entire surface, ensuring that they meet the required specifications for various applications. The bond strength between the rock wool core and the outer skins is critical for the panel’s durability and performance, and the machine’s heating and cooling systems play a key role in achieving strong, reliable bonds. Panels produced with these machines should exhibit excellent flatness, with no warping or deformation, and precise dimensional accuracy, allowing for easy installation and assembly. Energy efficiency is another important performance consideration, as heating and cooling systems can consume significant amounts of energy. Modern machines are designed with energy-saving features such as insulation for heating chambers, variable frequency drives for fans and pumps, and heat recovery systems that capture and reuse waste heat from the cooling process. These features not only reduce energy consumption but also lower operational costs, making the machine more cost-effective in the long run.

Operational stability is also a key performance metric, as downtime can be costly for manufacturers. These machines are built with durable components that can withstand the rigors of continuous operation, including high temperatures, pressure, and mechanical stress. The control system is designed to detect potential issues such as temperature deviations, material jams, or component malfunctions, providing alerts to operators and, in some cases, automatically shutting down the machine to prevent damage. Regular maintenance is required to ensure optimal operational stability, but the machine’s design should facilitate easy access to components for inspection and repair. Additionally, the machine should be easy to operate, with an intuitive HMI that allows operators to set parameters, monitor production, and troubleshoot issues with minimal training. This ease of operation reduces the risk of human error, further enhancing the machine’s performance and reliability.

Rock wool sandwich panel making machines with heating and cooling systems come in various types, each designed to meet specific production requirements, material types, and panel specifications. The primary classification of these machines is based on their production mode, with continuous production machines and batch production machines being the two main types. Continuous production machines are designed for high-volume production, operating continuously to produce long sheets of rock wool sandwich panels that are then cut into individual panels of the desired length. These machines are ideal for large-scale manufacturing facilities that require consistent production of standard-sized panels, as they offer high efficiency and low labor costs. Continuous production machines typically have a more complex structure, with integrated feeding, forming, heating, cooling, cutting, and stacking systems that operate in a synchronized manner. The heating and cooling systems in continuous machines are designed to handle the continuous flow of materials, providing uniform temperature control throughout the production process.

Batch production machines, on the other hand, are designed for small to medium-volume production, producing panels in batches rather than continuously. These machines are suitable for manufacturers that produce custom-sized panels or a variety of panel types, as they offer greater flexibility in terms of production parameters. Batch production machines typically have a simpler structure, with separate stations for feeding, forming, heating, cooling, and cutting. Each batch of panels is processed through these stations sequentially, allowing for adjustments to be made between batches to accommodate different panel specifications. The heating and cooling systems in batch machines are designed to heat and cool each batch of panels to the required temperature, with temperature control that can be adjusted for each batch. While batch production machines are less efficient than continuous machines in terms of output volume, they offer greater flexibility and are more cost-effective for small-scale production.

Another classification of these machines is based on the type of heating and cooling systems used. Some machines use electrical heating and forced air cooling, which are suitable for small to medium-scale production and offer precise temperature control. Others use hot air circulation heating and water cooling, which are more energy-efficient and suitable for high-volume production. There are also machines that utilize infrared heating, which provides fast and uniform heating, making them ideal for materials that require rapid bonding. Additionally, some machines are designed to handle specific types of outer skin materials, such as metal sheets, composite fabrics, or plastic sheets, with adjustments to the forming, heating, and cooling systems to accommodate the unique properties of each material. For example, machines producing panels with metal outer skins may require different heating temperatures to ensure proper bonding without damaging the metal, while machines producing panels with plastic skins may require more gentle cooling to prevent warping.

The size and capacity of the machine also vary, with small-scale machines designed for laboratory or small manufacturing facilities, and large-scale machines designed for industrial production. Small-scale machines typically have lower production speeds and smaller panel size capabilities, while large-scale machines can produce panels of varying widths and lengths at high speeds, meeting the demands of large construction projects or industrial applications. Some machines are also designed to be modular, allowing for easy expansion or modification of components to accommodate changing production needs. For example, a modular machine can have additional heating or cooling units added to increase production speed, or new forming tools added to produce different panel configurations.

The purpose of rock wool sandwich panel making machines with heating and cooling systems is closely tied to the applications of the rock wool sandwich panels they produce, which are known for their excellent thermal insulation, sound insulation, fire resistance, and structural strength. These panels are widely used in the construction industry, making the machines essential equipment for construction material manufacturers. In the building sector, rock wool sandwich panels are used for exterior walls, interior partitions, roofs, and floors of various types of buildings, including residential buildings, commercial buildings, industrial workshops, and public facilities. The thermal insulation properties of the panels help to reduce energy consumption for heating and cooling, making buildings more energy-efficient and environmentally friendly. The sound insulation properties make them ideal for use in buildings located in noisy areas, such as near highways or airports, while their fire resistance properties enhance building safety by slowing the spread of fire.

Industrial applications are another major area where these machines play a crucial role. Rock wool sandwich panels produced by these machines are used in the construction of industrial workshops, warehouses, and factories, where they provide insulation and protection against extreme temperatures, humidity, and noise. In industries such as petrochemical, power generation, and metallurgy, where high temperatures and fire risks are present, the fire resistance and heat insulation properties of the panels are particularly valuable. The panels are also used in the construction of clean rooms in industries such as electronics and pharmaceuticals, where a controlled environment with minimal dust and temperature fluctuations is required. Additionally, the panels are used in the construction of cold storage facilities, where their excellent thermal insulation properties help to maintain low temperatures, reducing energy consumption and preserving the quality of stored goods.

The transportation industry also utilizes rock wool sandwich panels produced by these machines, particularly in the manufacturing of vehicles such as trucks, trains, ships, and aircraft. In truck and trailer manufacturing, the panels are used for the construction of cargo boxes, providing thermal insulation for transporting temperature-sensitive goods such as food, pharmaceuticals, and chemicals. In the railway industry, the panels are used for the interior lining of train carriages, providing sound insulation and thermal comfort for passengers. In shipbuilding, the panels are used for the construction of ship cabins and bulkheads, offering fire resistance and thermal insulation in harsh marine environments. In the aviation industry, lightweight rock wool sandwich panels are used for the interior of aircraft, providing sound insulation and fire protection while minimizing weight, which is critical for fuel efficiency.

Another important application area is the agricultural sector, where rock wool sandwich panels are used in the construction of greenhouses, livestock sheds, and agricultural warehouses. The thermal insulation properties of the panels help to maintain stable temperatures inside greenhouses, creating optimal growing conditions for plants throughout the year. In livestock sheds, the panels provide insulation and sound insulation, improving the living conditions for animals and reducing stress. The fire resistance properties also help to protect agricultural facilities from fire damage, which can be devastating for farmers. Additionally, the panels are used in the construction of agricultural warehouses for storing crops, fertilizers, and equipment, providing protection against moisture, pests, and extreme temperatures.

Beyond these major sectors, rock wool sandwich panels produced by these machines are also used in various other applications, such as the construction of modular buildings, portable cabins, and emergency shelters. Modular buildings, which are prefabricated off-site and assembled on-site, rely heavily on rock wool sandwich panels for their speed of construction and excellent performance. Portable cabins and emergency shelters, used for temporary housing in disaster-stricken areas or construction sites, benefit from the lightweight, durable, and easy-to-install nature of the panels. The panels are also used in the renovation and retrofitting of existing buildings, where they can be added to improve insulation, soundproofing, and fire safety without major structural modifications.

In conclusion, rock wool sandwich panel making machines with heating and cooling systems are sophisticated pieces of equipment that play a vital role in the production of high-quality rock wool sandwich panels. Their complex structure, which integrates feeding, forming, heating, cooling, control, cutting, and stacking components, ensures efficient and consistent production. The performance of these machines, characterized by high production efficiency, precise temperature control, consistent panel quality, energy efficiency, and operational stability, makes them indispensable for manufacturers across various sectors. The different types of machines, including continuous and batch production machines, cater to a wide range of production needs, from small-scale custom production to large-scale industrial output. The diverse applications of the rock wool sandwich panels they produce, spanning construction, industrial, transportation, agricultural, and other sectors, highlight the importance of these machines in modern manufacturing and society as a whole. As the demand for energy-efficient, safe, and durable building materials continues to grow, the role of these machines will only become more critical, driving innovation in their design and performance to meet the evolving needs of the industry.

Related

Marine Composite Rock Wool Board Production Line

Rock Wool Board Equipment

Steel Edge Sealing Rock Wool Sandwich Panel Machine

Polyurethane Fireproof Rock Wool Sandwich Panel Production Line

Polyurethane Rock Wool Sandwich Panel Machine

Polyurethane Edge Sealing Rock Wool Sandwich Panel Machine

Rock Wool Sandwich Panel Production Line with Automatic Slitting System

Rock Wool Board Production Line For Sound Insulation

Double Track Rock Wool Sandwich Panel Line

Rock Wool Sandwich Panel Manufacturing Line for Industrial Building