PU Sandwich Panel Manufacturing Equipment For Energy Saving Project

In the global pursuit of sustainable development and energy efficiency, the construction and industrial sectors are increasingly turning to materials and technologies that minimize energy consumption while ensuring structural performance. Polyurethane (PU) sandwich panels have emerged as a leading solution in this context, thanks to their exceptional thermal insulation properties, lightweight structure, and durability. These panels, composed of a PU foam core sandwiched between two metal facings, play a crucial role in reducing heat transfer in buildings and industrial facilities, thereby lowering energy demands for heating and cooling systems. Behind the production of these high-performance panels lies a sophisticated system of manufacturing equipment, whose efficiency, precision, and adaptability directly influence the quality and energy-saving effectiveness of the final products. As energy-saving projects continue to expand across various industries—from cold storage and logistics hubs to industrial warehouses and commercial buildings—the significance of advanced PU sandwich panel manufacturing equipment becomes increasingly prominent.

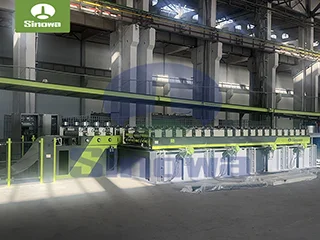

The fundamental functionality of PU sandwich panel manufacturing equipment revolves around transforming raw materials into integrated composite panels through a continuous, automated process. Unlike traditional manual production methods, modern manufacturing lines ensure consistency in panel quality, enhance production efficiency, and enable customization to meet the specific requirements of different energy-saving projects. The core of this equipment system is a series of interconnected modules, each designed to perform a specific function in the production chain, from material feeding and forming to foam injection, curing, and cutting. The seamless coordination between these modules is essential to maintaining the integrity of the sandwich panel structure, as any discrepancy in processing can compromise the thermal insulation performance and structural stability of the final product—key factors in the success of energy-saving initiatives.

The production process begins with the uncoiling and feeding module, which handles the metal coils that will form the outer and inner facings of the sandwich panels. Common metal materials used include galvanized steel, galvalume, and aluminum, chosen for their strength, corrosion resistance, and compatibility with the PU foam core. The uncoiling equipment is designed to safely unwind large metal coils, with tension control mechanisms to prevent deformation of the metal sheets. After uncoiling, the metal sheets are fed into the roll forming module, where they are progressively shaped into the desired profile through a series of tandem rolling stands. Each rolling stand applies precise pressure to bend the metal sheet incrementally, ensuring that the final profile—whether for wall panels, roof panels, or specialized applications—meets the dimensional accuracy required for proper installation and thermal insulation. The roll forming process is highly adaptable, allowing for the production of panels with varying widths, lengths, and profile designs to suit different energy-saving project needs, such as the curved panels used in some modern commercial buildings or the ribbed panels for industrial warehouses.

Following the roll forming stage, the shaped metal sheets move to the PU foam injection module, a critical part of the manufacturing process that determines the energy-saving performance of the final panel. The PU foam core is the primary insulator, with a closed-cell structure that minimizes heat transfer through convection and conduction. The injection equipment consists of a high-pressure mixing system that combines polyol and isocyanate— the two main components of PU foam—along with additives such as blowing agents and catalysts. The mixing process must be precise, as the ratio of components directly affects the density, thermal conductivity, and bonding strength of the foam. Modern injection systems use computerized metering pumps to ensure accurate component ratios, even at high production speeds. The foam mixture is then continuously injected between the two moving metal sheets, which are kept at a specific distance by side sealing devices to maintain the desired core thickness. The choice of blowing agent is particularly important for energy-saving and environmental sustainability; many modern systems use hydrofluorocarbon-free blowing agents that reduce the carbon footprint of the panels while maintaining their insulation efficiency.

Once the foam is injected, the composite structure enters the cooling and curing module, where the foam expands and solidifies to form a strong bond with the metal facings. The curing process requires precise temperature control to ensure that the foam achieves its optimal physical properties. Many manufacturing lines use hot air circulation ovens or double-belt conveyors with temperature-regulated surfaces to maintain a consistent curing environment. The double-belt conveyor system is particularly effective, as it applies uniform pressure to the top and bottom of the panel while controlling temperature, ensuring that the foam cures evenly and the panel maintains a flat, uniform surface. The cooling phase that follows allows the panel to stabilize, preventing warping or deformation as it exits the production line. The duration of cooling and curing depends on factors such as the core thickness, foam density, and ambient temperature, with automated systems adjusting parameters to maintain consistent quality across different production runs.

After curing and cooling, the continuous panel is fed into the cutting module, where it is precision-cut to the required length using automated cutting machines. These machines use high-speed blades or saws controlled by computer numerical control (CNC) systems, ensuring accurate cuts even at high production speeds. Some advanced systems also integrate additional processes at this stage, such as punching for fastener holes, embossing for surface texture, or edge trimming for improved installation fit. The cut panels are then automatically transferred to a stacking or packaging module, where they are sorted, stacked, and prepared for transportation. This final stage of the process is designed to minimize damage to the panels during handling, ensuring that they arrive at the construction site in optimal condition—critical for maintaining their thermal insulation performance and structural integrity in energy-saving projects.

The technical characteristics of modern PU sandwich panel manufacturing equipment are closely aligned with the needs of energy-saving projects, emphasizing efficiency, precision, and environmental sustainability. One of the key features of advanced equipment is its automation level, which reduces human error, increases production speed, and lowers energy consumption during manufacturing. Computerized control systems, often based on programmable logic controllers (PLC), monitor and adjust every stage of the production process, from material feeding to cutting, ensuring that parameters such as foam density, core thickness, and curing temperature are maintained within tight tolerances. This automation not only improves product consistency but also allows for real-time data collection and analysis, enabling manufacturers to optimize processes for greater energy efficiency and reduce waste.

Another important technical characteristic is the flexibility of the equipment, which allows for the production of panels with varying specifications to suit different energy-saving applications. For example, cold storage facilities require panels with thick, high-density foam cores to maintain low temperatures and minimize refrigeration energy consumption, while industrial warehouses may use thinner panels with optimized structural strength for roof applications. Modern manufacturing lines can quickly switch between different panel configurations, adjusting core thickness, metal sheet thickness, and profile design without significant downtime. This flexibility is essential for meeting the diverse needs of energy-saving projects across industries, from agricultural buildings and livestock facilities to cleanrooms and prefabricated commercial structures.

Energy efficiency in the manufacturing process itself is also a key consideration, as it contributes to the overall sustainability of the PU sandwich panels. Advanced equipment incorporates energy-saving technologies such as variable frequency drives (VFD) for motors, which adjust speed based on production demand to reduce power consumption, and heat recovery systems that capture waste heat from the curing process for reuse in preheating metal sheets or heating the production facility. Additionally, the use of low-emission components and environmentally friendly materials in the equipment, such as non-toxic lubricants and recyclable parts, further enhances the sustainability of the production process, aligning with the goals of energy-saving projects that prioritize reduced carbon footprints.

The role of PU sandwich panel manufacturing equipment in energy-saving projects extends beyond the production of high-quality panels; it also enables the efficient implementation of these projects by supporting rapid construction and reducing installation costs. PU sandwich panels are prefabricated, meaning they can be installed quickly on-site, reducing construction time and labor requirements compared to traditional building materials such as brick or concrete. The precision of the manufacturing equipment ensures that the panels fit together seamlessly, with interlocking joints that minimize air leakage— a major source of energy loss in buildings. This tight fit, combined with the excellent thermal insulation of the PU foam core, results in significant energy savings for the end user. For example, in cold storage facilities, the use of PU sandwich panels produced by advanced equipment can reduce refrigeration energy consumption by up to 40%, while in commercial buildings, they can lower heating and cooling costs by 30% or more compared to traditional insulation materials.

In addition to their direct energy-saving benefits, PU sandwich panels manufactured by advanced equipment contribute to the durability and longevity of buildings and industrial facilities, reducing the need for frequent maintenance and replacement—another factor in long-term energy and cost savings. The combination of rigid metal facings and high-density PU foam core provides excellent resistance to harsh weather conditions, moisture, UV radiation, and impact damage. This durability ensures that the panels maintain their thermal insulation performance over time, avoiding the degradation that can occur with traditional insulation materials. For energy-saving projects in extreme climates, such as arctic cold storages or desert solar farms, this durability is particularly critical, as it ensures consistent energy efficiency even in challenging environmental conditions.

The future development of PU sandwich panel manufacturing equipment is likely to be driven by ongoing advancements in materials science, automation technology, and the growing demand for sustainable, energy-efficient solutions. One area of innovation is the development of equipment capable of processing bio-based PU foams, which use renewable raw materials such as vegetable oils instead of petroleum-based products. This would further reduce the carbon footprint of the panels, aligning with global efforts to transition to a circular economy. Another trend is the integration of artificial intelligence (AI) and machine learning into manufacturing systems, enabling predictive maintenance, real-time process optimization, and enhanced quality control. AI-powered systems can analyze data from sensors throughout the production line to identify potential issues before they affect product quality, reducing downtime and waste.

Additionally, there is a growing focus on improving the energy efficiency of the manufacturing equipment itself, with the development of more efficient motors, heat recovery systems, and energy storage solutions. This will not only reduce the environmental impact of the production process but also lower manufacturing costs, making PU sandwich panels more accessible for a wider range of energy-saving projects. The integration of digital twin technology is another promising development, allowing manufacturers to create virtual models of the production line to simulate and optimize processes before implementation, further improving efficiency and reducing the risk of errors.

In conclusion, PU sandwich panel manufacturing equipment plays a vital role in supporting the global transition to energy-efficient, sustainable construction and industrial practices. Its ability to produce high-quality, consistent, and customizable panels with exceptional thermal insulation properties directly contributes to the success of energy-saving projects across various industries. From the automated uncoiling and roll forming stages to the precise foam injection, curing, and cutting processes, every component of the manufacturing equipment is designed to ensure that the final panels meet the strict performance requirements of modern energy-saving initiatives. As technology continues to advance, the future of PU sandwich panel manufacturing equipment promises even greater efficiency, sustainability, and adaptability, further enhancing the role of PU sandwich panels in reducing energy consumption and mitigating the impact of climate change. For energy-saving projects seeking to balance performance, cost-effectiveness, and environmental responsibility, investing in advanced PU sandwich panel manufacturing equipment is not only a practical choice but also a commitment to a more sustainable future.

Related

PU Sandwich Panel Manufacturing Machinery For Double-sided Composite Panels

PU Sandwich Panel Plant For Composite Board Production

Polyurethane Sandwich Panel Making Machine For High Strength Composite Panel Production

Sandwich Panel Forming Machine

PIR Sandwich Panel Machine For Prefabricated House Panels

PU Sandwich Panel Manufacturing Machinery For Wall Panel Production

Thermal Insulation Decorative Sandwich Panel Machine

Energy-Efficient PU Sandwich Panel Making Line With Low Power Consumption

PU Sandwich Panel Machine With Auto Packer

PU Sandwich Panel Machine Manufacturer From China