PU Sandwich Panel Line With Double Belt Press And Cooling Tunnel

The modern polyurethane (PU) sandwich panel production line integrates dual belt press technology and advanced cooling channel system, representing the highest level of current building panel manufacturing. This production line is specifically designed for producing polyurethane sandwich panels with excellent thermal insulation properties, which are widely used in cold chain logistics, industrial plants, commercial buildings, and other fields.

The entire system consists of six core modules: raw material supply, automatic mixing, double belt press molding, cooling and solidification, automatic cutting, and stacking and packaging, achieving a fully automated production process from raw materials to finished products. Compared with traditional single belt press production lines, the dual belt press system can achieve more precise thickness control, higher production efficiency, and better product consistency.

Core technology of dual belt press system

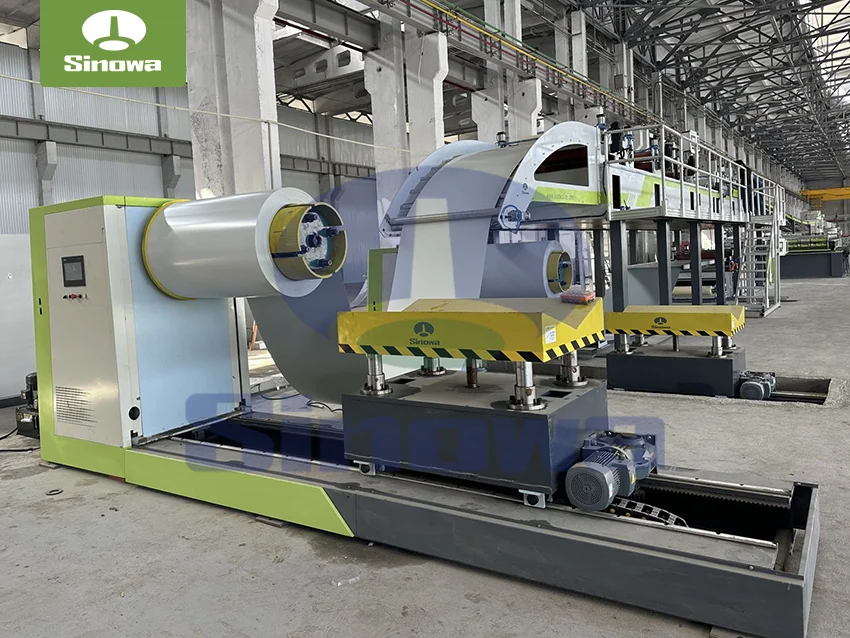

The double belt press is the core equipment of the pu sandwich panel production line, consisting of two high-strength steel strips, a pressure system, a heating system, and a precision control system.

Steel strip system:

High strength alloy steel strip is used, with a thickness usually between 1.2-2.0mm, and the surface is specially treated to ensure smoothness and flatness

The width of the steel strip can be customized according to product requirements, with common widths of 1200mm, 1000mm, etc

Equipped with an automatic correction device to ensure precise movement trajectory of the steel stripPressure control system:

The hydraulic system provides uniform pressure, with a pressure range typically adjustable from 5-20 bar

Partition pressure control technology can independently adjust the pressure in each zone according to the width and thickness requirements of the board

Control pressure fluctuations within ± 0.5bar to ensure uniform product densityHeating system:

Using hot oil or electric heating method, temperature control accuracy ± 1 ℃

The heating zone is divided into preheating zone, main heating zone, and insulation zone, with programmable temperature gradient control

The maximum working temperature can reach 200 ℃, meeting the foaming needs of different formulations of polyurethaneIntelligent control system:

PLC+touch screen human-machine interface, real-time monitoring of parameters such as pressure, temperature, speed, etc

Equipped with fault self diagnosis and alarm functions

Automatic recording and storage of production data, supporting quality traceability

Design of cooling channel system

The cooling channel is a key link to ensure stable product quality, located at the outlet end of the double belt press. Its main function is to quickly reduce the temperature of the sheet and stabilize the product size.

Cooling method:

Air cooling system: Multiple fan units combined with deflectors to achieve uniform forced air cooling

Water cooling system (optional): Built in cooling water pipes for rapid cooling through heat exchange

Combination cooling: combining air and water cooling, suitable for high-density board productionTemperature control:

Partition temperature control, adjustable cooling gradient

Control the temperature of the board below 40 ℃

Equipped with an infrared thermometer to monitor the surface temperature of the board in real-timeStructural features:

The length is usually 6-12 meters, designed according to production capacity requirements

The internal guide rollers are made of special materials to prevent scratches on the surface of the board

Adjustable wind speed design to meet the cooling needs of different thickness plates

Process flow of polyurethane sandwich panel production line

Raw material preparation stage:

Polyether/polyester polyols, isocyanates and other raw materials are accurately measured and transported to the high-pressure foaming machine

Metal panels (color steel plates, stainless steel, etc.) are cleaned and pre treated before entering the production lineMixing injection stage:

The high-pressure foaming machine mixes the raw materials and injects them between the upper and lower metal panels

The injection amount is automatically adjusted according to the thickness of the board, with an accuracy of ± 1%Foam compression stage:

The mixture is foamed and compressed into shape in a double belt press

Accurate control of foaming process and board density through temperature and pressure

Typical foaming time 30-120 seconds, depending on thicknessCooling and shaping stage:

The formed sheet enters the cooling channel and gradually cools down to a stable state

The cooling time is usually 5-15 minutesPost processing stage:

The automatic cutting system cuts the sheet according to the set length

Robot arm automatic stacking, packaging and storage

Technological innovation and advantages of polyurethane sandwich panel line

Efficient production: The continuous production method of dual belt press increases the efficiency by 3-5 times compared to traditional intermittent production

Stable quality: Accurate temperature and pressure control ensures consistent product performance

Energy saving and environmental protection: The heat recovery system can recycle more than 30% of the heat energy, reducing energy consumption

Flexible adaptation: Quick mold change design, capable of producing products of different thicknesses and widths

Intelligent control: MES system integration, realizing real-time monitoring and analysis of production data

Expansion of application fields

In addition to the traditional field of building insulation, products produced by modern polyurethane sandwich panel production lines can also be applied to:

Cold chain logistics: refrigerated truck body, cold storage panel

Clean engineering: clean room partitions in hospitals and electronic factories

Shipbuilding: Marine insulated bulkheads

Special vehicles: Lightweight panels for RVs and military vehicles

Maintenance and upkeep points

To ensure the long-term stable operation of the pu sandwich panel line, attention should be paid to:

Regularly inspect the surface condition of the steel strip and promptly repair scratches

Regularly replace filters and hydraulic oil in the hydraulic system

Regularly clean the radiator of the cooling system to maintain good ventilation

The mixing head of the foaming machine is cleaned daily to prevent solidification and blockage

Regularly check the wiring and sensor status of the electrical system

With the increasing requirements for building energy efficiency and the development of intelligent manufacturing, the polyurethane sandwich panel manufacturing line equipped with dual belt presses and advanced cooling channels will continue to be upgraded and optimized, moving towards higher efficiency, more precise control, and greener environmental protection, providing high-quality insulation solutions for building industrialization.

Related

PIR Insulated Sandwich Panel Machine

Cold Room Panel Production Line

PU Sandwich Panel Continuous Production Line

PU Isolation Board Production Line

Wall PU Sandwich Panel Machine

Clean Room Sandwich Panel Machine

Exterior Wall PU Sandwich Panel Machine

Insulation Sandwich Panel Machine

PU Sandwich Panel Line With Edge Trimming And Hole Punching Functions

Heavy-duty PU Sandwich Panel Production Line For Industrial Building Panels