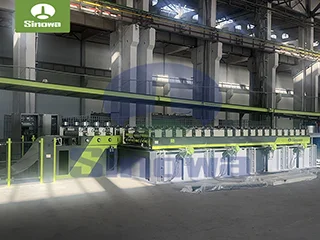

Industrial Sandwich Panel Line

The Industrial Sandwich Panel Line is a specialized assembly line equipment for producing sandwich panels. As an important industrial material, sandwich panels have a wide range of applications in fields such as construction, transportation, and home appliances.

Industrial Sandwich Panel Lines are usually composed of multiple parts, including raw material preparation area, mixing foaming area, molding area, curing area, cutting area, and packaging area. These areas are closely connected through automated equipment and conveyor belts, forming a complete production process.

Working principle

Raw material preparation: prepare the required core materials (such as rock wool, glass wool, polyurethane foam, etc.) and panel materials (such as color steel plate, aluminum plate, etc.), and conduct pretreatment, such as cutting, cleaning, gluing, etc.

Mixed foaming: Polyurethane solution or other foaming materials are mixed in a certain proportion into a mixing head, and then foamed under high pressure and evenly poured onto the bottom surface material of the sandwich panel.

Molding: Cover the upper layer of surface material with foam material, and press the sandwich panel into shape through molding equipment to ensure the flatness and uniform thickness of the panel.

Curing: The molded sandwich panel is sent to the curing zone for heating and curing, allowing the foam material to fully cure and tightly bond with the panel material.

Cutting: Use an automatic tracking cutting machine to cut the cured sandwich panel according to the required size and shape.

Packaging: Pack and label the cut sandwich panels for transportation and storage.

Product Features

Efficiency: The Industrial Sandwich Panel Line adopts automated equipment and assembly line operations, greatly improving production efficiency.

Flexibility: The Industrial Sandwich Panel production line can be adjusted according to different sandwich panels and panel materials to meet the needs of different customers.

Accuracy: By using high-precision measuring and cutting equipment, the size and shape of the sandwich panel are ensured to be accurate and error free.

Environmental friendliness: The use of eco-friendly foam and panel materials reduces the impact on the environment.

Industrial sandwich panels are widely used in fields such as construction, transportation, and home appliances due to their excellent insulation, sound insulation, and fire resistance properties. This includes but is not limited to:

In the field of architecture, it is used for structures such as walls, roofs, and floors to provide insulation, sound insulation, fire prevention, and other functions.

Transportation: Used for interior decoration and sound insulation of vehicles such as cars, trains, and ships.

In the field of household appliances, it is used to make insulation layers for refrigerators, air conditioners, and other household appliances.

With the continuous development of digitalization and automation technology, Industrial Sandwich Panel Lines will move towards a more intelligent, efficient, and environmentally friendly direction. In the future, production lines will increasingly adopt technologies such as the Internet of Things, big data, and artificial intelligence to achieve intelligent monitoring and management of the production process, improving production efficiency and product quality. Meanwhile, with the continuous improvement of environmental awareness, production lines will pay more attention to the use of environmentally friendly materials and energy-saving technologies to reduce their impact on the environment.

The Industrial Sandwich Panel Line as an important equipment for producing sandwich panels, has the characteristics of high efficiency, flexibility, precision, and environmental friendliness, and has a wide range of applications in multiple fields. In the future, with the continuous advancement of technology and the improvement of environmental awareness, production lines will develop towards a more intelligent, efficient, and environmentally friendly direction.

Related

High Quality PU Sandwich Panel Machine Design

Corrugated Sandwich Panel Production Line

External Wall Composite Insulation Board Production Line

Sandwich Panel Forming Machine

Thermal Insulation Decorative Sandwich Panel Machine

PU Sandwich Panel Machine Manufacturer From China

Sandwich Panel Line For Cold Storage

PIR Insulated Sandwich Panel Machine

Cold Room Panel Production Line

PU Sandwich Panel Continuous Production Line