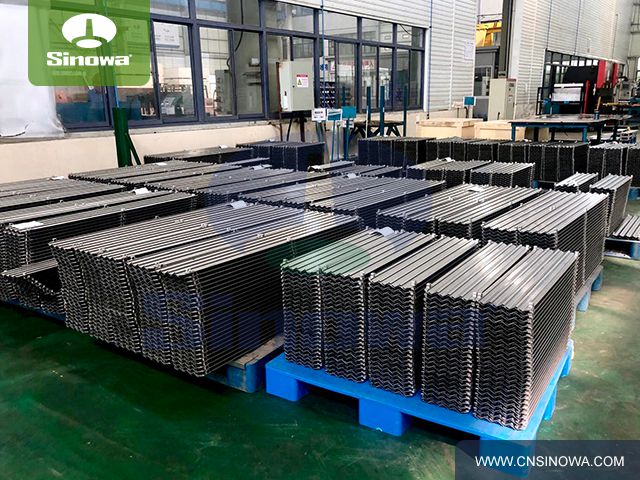

Continuous PU/PIR Sandwich Panel Production Line

Dedicated to the research and development of high-end and high-efficiency sandwich panel production lines, Sinowa is comprehensively taking the leading position in terms of efficiency, automation control level, HMI, environment protection and energy consumption, with subversive designs made in some critical technological fields to procure exceptional cost performance and customer-friendly experience for the entire production line.